Fall 2019 senior design projects

Projects

- Speaker/Microphone System for ALS Patient with Air Mask

- Accessible Grocery Bag Solution for Motorized Wheelchair

- Fishing Rod and Reel System for Paraplegic Operation

- Commercial Vehicle Universal Carrier Stand for Inspection and Analysis

- Designing and Optimizing a 3D Printed Violin for Limited Access Children

- Wheelchair Lift Concept for Autonomous Vehicles

- Autonomous Vehicle Shuttle Route Development

- Making Autonomous Vehicles Accessible

- Thermally Controlled Sample Stage for Solar Cell Irradiance Chamber

- Quantitative Measurement of Algal Scum

- Imagination Station Hovercraft

- UT Facilities Boiler System Improvements

- Design of an Integrated LED Display Stainless Steel Waste Receptacle

- UAV Camera Deployment System for Woodpecker Nest Observations

- Design of a 3D-Printed Universal Joint Travel Kit

- Test Fixture for Dana NVH Lab

- Mechanical Arm for Automated Plastic Wrapping of Material Rolls

- Control Freedom for Theatre Performer with Muscular Dystrophy

- Step-Lift System for Wheelchairs

- Let's Crank It!: Historic R4360 Aircraft Engine Restoration

- Design of End of Arm Tooling and Conveyor Pallet for new product line

- Spark Plug Thermal Shock Tester

- Therma-Tru Water and Air Measurement System Evaluation

Our Client, Phillis Lopez is someone who suffers from a disease known as ALS (Amyotrophic lateral sclerosis) or Lou Gehrig’s disease. ALS is an incurable disease that affects the nerve cells

in the brain and spinal cord. The nerve cells in those regions are not provided nourishment

which then leads to the cells wasting away. When the cells waste away it causes scarring

and that scarring leads to hardening. As these cells continue to die off an eventual

loss of motor functions will occur as well as the inability to control voluntary muscles.

After these motor neurons have died off, a person can lose the ability to breathe,

speak, eat, or move. Our client Phillis has difficulty breathing because of this and

thus must wear an air mask that pumps air into her lungs. The only time the air mask

is taken off is when she eats and often must be put back on before she can finish

her food due to shortness of breath. Because of this, she needs a system to properly amplify her voice to be able to communicate

effectively again.

Our Client, Phillis Lopez is someone who suffers from a disease known as ALS (Amyotrophic lateral sclerosis) or Lou Gehrig’s disease. ALS is an incurable disease that affects the nerve cells

in the brain and spinal cord. The nerve cells in those regions are not provided nourishment

which then leads to the cells wasting away. When the cells waste away it causes scarring

and that scarring leads to hardening. As these cells continue to die off an eventual

loss of motor functions will occur as well as the inability to control voluntary muscles.

After these motor neurons have died off, a person can lose the ability to breathe,

speak, eat, or move. Our client Phillis has difficulty breathing because of this and

thus must wear an air mask that pumps air into her lungs. The only time the air mask

is taken off is when she eats and often must be put back on before she can finish

her food due to shortness of breath. Because of this, she needs a system to properly amplify her voice to be able to communicate

effectively again.

Team Members: Lucas Sturt, Matthew Lezon, Mitchel Bumb, Mohammed Almutairi

Team Members: Lucas Sturt, Matthew Lezon, Mitchel Bumb, Mohammed Almutairi

Faculty Advisor: Dr. Mohammed Hefzy

Client Advisor: Phillis Lopez

Project Sponsor: University of Toledo

Special Thanks: Dr. Brian Trease

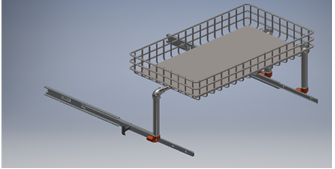

Project Description: The objective of this project is to design, analyze, test and build an attachable

grocery bag solution for a motorized wheelchair. This attachment is being designed

in order to assist our client when she goes grocery shopping at the store. Our client

currently can attach one to two bags on a hook behind her head-rest, thus she makes

multiple trips every week just to get the bare minimum of her household groceries.

The proposed design adds slides that attach to the T-rail base of the wheelchair and

lock in a non-extended position and easily extendable for use. At the end of the slides, is a mounting point for a detachable wireframe basket

so that the client can easily store and carry more than 50 lbs. of groceries per trip.

Project Description: The objective of this project is to design, analyze, test and build an attachable

grocery bag solution for a motorized wheelchair. This attachment is being designed

in order to assist our client when she goes grocery shopping at the store. Our client

currently can attach one to two bags on a hook behind her head-rest, thus she makes

multiple trips every week just to get the bare minimum of her household groceries.

The proposed design adds slides that attach to the T-rail base of the wheelchair and

lock in a non-extended position and easily extendable for use. At the end of the slides, is a mounting point for a detachable wireframe basket

so that the client can easily store and carry more than 50 lbs. of groceries per trip.

Team Members: Benjamin Davis, Almuhannad Alghamdi, Jordan Orians, Michael Geckler

Team Members: Benjamin Davis, Almuhannad Alghamdi, Jordan Orians, Michael Geckler

Faculty Advisor: Dr. Mohamed Samir Hefzy

Client Advisor: Becky Opperman

Project Sponsor: The Ability Center of Toledo & The University of Toledo

Our client, Hank Barney, endured a spinal injury that greatly hindered movement in

his fingers and legs. He enjoys fishing, so he wanted to get a brace that would allow

him to continue fishing despite his disability. He had a splint specially made for

him to use, which is formed to his left forearm and also contains a metal bar for

mounting fishing poles to the splint. Our objectives for Hank’s splint were to develop

a mounting system for a fishing pole that was lightweight, easy to use, and refrained

from causing harm to Hank. Our design needs to be lightweight so that Hank can keep

fishing longer without feeling fatigued. Hank fishes with at least one other person

with him, usually either his father or his aide. Our design needs to be easy to use

so that whoever helps him switch out fishing rods will have as little issues as possible

while helping Hank. Lastly, Hank’s safety is of utmost importance, so our design

will need to cause him no harm.

Our client, Hank Barney, endured a spinal injury that greatly hindered movement in

his fingers and legs. He enjoys fishing, so he wanted to get a brace that would allow

him to continue fishing despite his disability. He had a splint specially made for

him to use, which is formed to his left forearm and also contains a metal bar for

mounting fishing poles to the splint. Our objectives for Hank’s splint were to develop

a mounting system for a fishing pole that was lightweight, easy to use, and refrained

from causing harm to Hank. Our design needs to be lightweight so that Hank can keep

fishing longer without feeling fatigued. Hank fishes with at least one other person

with him, usually either his father or his aide. Our design needs to be easy to use

so that whoever helps him switch out fishing rods will have as little issues as possible

while helping Hank. Lastly, Hank’s safety is of utmost importance, so our design

will need to cause him no harm.

Team Members: Bryce Cordonnier – Group Leader; Lukas Gigandet – Technical Liaison; Kyle Bussing – Purchasing Agent; Matthew Mujic – Communication Specialist

Team Members: Bryce Cordonnier – Group Leader; Lukas Gigandet – Technical Liaison; Kyle Bussing – Purchasing Agent; Matthew Mujic – Communication Specialist

Faculty Advisor: Dr. Hefzy; Client Advisor: Mr. “Hank” Burnard Barney III, The Ability Center of Greater Toledo

Project Sponsor: The University of Toledo- College of Engineering, MIME Department

Special Thanks: Dr. Trease, Dr. Hefzy, Nick Michael, Hank Barney, Angie Goodnight

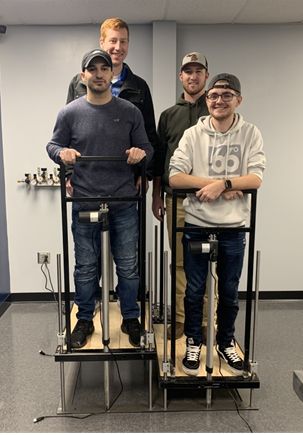

This group was tasked to build a stand that can bolt/mount to a commercial vehicle

axle carrier so that DANA can implement their new process called Design Review by

Test Results (DRBTR). For this, the stand must be universal for all the different

axle carriers that DANA currently has in use or will possibly have in the future. The stand

must be able to rotate easily for the engineers and customers to observe the top and

bottom sides of the carrier. This allows for all parties to more easily locate any

abnormalities that would have caused specific areas in the axle carriers to fail in testing

done prior to the DRBTR test.

This group was tasked to build a stand that can bolt/mount to a commercial vehicle

axle carrier so that DANA can implement their new process called Design Review by

Test Results (DRBTR). For this, the stand must be universal for all the different

axle carriers that DANA currently has in use or will possibly have in the future. The stand

must be able to rotate easily for the engineers and customers to observe the top and

bottom sides of the carrier. This allows for all parties to more easily locate any

abnormalities that would have caused specific areas in the axle carriers to fail in testing

done prior to the DRBTR test.

Team Members: Ethan Warncke, Conlan Hipp, Andrew Malcolm, and Samuel Huelskamp

Faculty Advisor: Dr. Ala Qattawi

Client Advisor: Tyler Girt

Project Sponsor: Dana

Special Thanks: Jamie Smith, Shop Fabricator; Mike Gelske, Shop Machinist

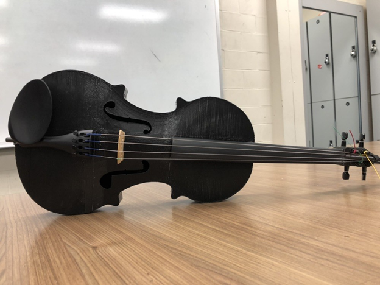

The goal of this project was to be able to provide access to violins for underprivileged

or remote location children utilizing 3D Printing technology. Entry-level violins can cost anywhere from $400 to $2000 dollars and most children

end up renting them or not playing at all. Sponsored by the Toledo Symphony Orchestra, this project pushed us to create a 3D printed violin that was affordable and held a

good level of sound quality. Our group used modeling software and design analysis to ensure that we would deliver

an end result violin that was affordable, durable, easy to assemble and produced a good quality of sound. We were able to create a violin design that can be fabricated, assembled, and played

for around $160. Our clients with the Toledo Symphony were able to play and hear the violin we created,

and it exceeded their expectations. Overall this was a fun project to work on and

we are very happy with the results.

The goal of this project was to be able to provide access to violins for underprivileged

or remote location children utilizing 3D Printing technology. Entry-level violins can cost anywhere from $400 to $2000 dollars and most children

end up renting them or not playing at all. Sponsored by the Toledo Symphony Orchestra, this project pushed us to create a 3D printed violin that was affordable and held a

good level of sound quality. Our group used modeling software and design analysis to ensure that we would deliver

an end result violin that was affordable, durable, easy to assemble and produced a good quality of sound. We were able to create a violin design that can be fabricated, assembled, and played

for around $160. Our clients with the Toledo Symphony were able to play and hear the violin we created,

and it exceeded their expectations. Overall this was a fun project to work on and

we are very happy with the results.

Team Members: Graham Fitkin, Alexei Groff, Trent Jones, Adam Kemerer, Caroline Shipman

Team Members: Graham Fitkin, Alexei Groff, Trent Jones, Adam Kemerer, Caroline Shipman

Faculty Advisor: Dr. Matthew Franchetti

Client Advisor: Merwin Siu - The Toledo Symphony; Alain Trudel - The Toledo Symphony; Zak Vassar - The Toledo Symphony;

Project Sponsor: The Toledo Symphony Orchestra

Special Thanks: Kim Mcintosh, UT Makerspace, MIME Graduate Student Nicholas Michael, Rettig Music

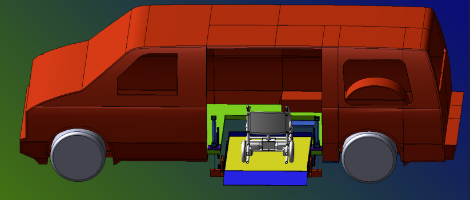

Our design team was tasked by our client, DriveOhio, to make autonomous vehicles more accessible, specifically for people with disabilities.

This task was open-ended and required our team to come up with a solution to solve

this issue. Our team evaluated different types of disabilities and how they affect

an individual’s ability to access vehicles. We found that the majority of vehicle accessibility issues come from individuals that are in wheelchairs. We met

with our client and discussed how for our project we wanted to design a wheelchair

lift that would allow people in wheelchairs to access autonomous vehicles.

Our design team was tasked by our client, DriveOhio, to make autonomous vehicles more accessible, specifically for people with disabilities.

This task was open-ended and required our team to come up with a solution to solve

this issue. Our team evaluated different types of disabilities and how they affect

an individual’s ability to access vehicles. We found that the majority of vehicle accessibility issues come from individuals that are in wheelchairs. We met

with our client and discussed how for our project we wanted to design a wheelchair

lift that would allow people in wheelchairs to access autonomous vehicles.

The solution to this problem is a wheelchair lift that can be seamlessly retrofitted into the floor of an autonomous vehicle. We have created a three-dimensional model that outlines the design of our concept that will be delivered to DriveOhio, as well as a prototype that can simulate the motion needed. Power and Stress analyses were conducted throughout the project in order to maintain safety and used to select the necessary components needed.

Team Members: Alex Theis, Vighnesh Nayak, Nicholaus Cipriano, Evan Garrity,

Team Members: Alex Theis, Vighnesh Nayak, Nicholaus Cipriano, Evan Garrity,

Faculty Advisor: Matthew Franchetti

Client Advisor: Jennifer Schlegel

Project Sponsor: AAA Northwest Ohio

Special Thanks: Tim and John -University of Toledo Machine Shop, Adam Schroeder, Debbie Fallon- Sunshine Communities

We worked with DriveOhio and TMACOG to gather data to help develop route options for an autonomous shuttle in the downtown Toledo area. The goal was to allow people a more convenient means of travel, especially for individuals who do not own or are unable to operate a vehicle. We also believed that we could help connect downtown with the University of Toledo. The shuttles will operate on a first/last mile system where one shuttle circulates on the University of Toledo campus with the intent for it to be connected to the downtown circulators by means a user-operated shuttle. In order to develop the routes for these shuttles, data was collected through the form of a survey that was distributed to the student body. The intent of the survey was to gather information on transportation, interests, and expectations for an autonomous shuttle. After compiling the survey results, we were able to map three route options that we believe would play into the current capabilities of autonomous vehicles as well as fit the community’s needs.

Team Members: Jacob Mezera, Mitch Hering, Silas Kreuz, Gunj Dedhia

Faculty Advisor: Dr. Matt Franchetti

Client Advisor: Rich Granger, DriveOhio

Project Sponsor: DriveOhio & AAA of Northwest Ohio

Special Thanks: Rich Granger, Andrew Bremer & the rest of the DriveOhio team; Dave Gedeon & the TMACOG team

Nationally, almost 15 million people have difficulties getting the transportation they require. Of these, about 6 million (i.e. 40 percent) are people with disabilities. (Bureau of Transportation Statistics) Autonomous vehicles are a promising solution. The self-driving shuttles developed are being tested in Columbus but are not accessible to people with disabilities. The interior of these shuttles feels crowded. Our aim is to help design an interior, specifically for autonomous vehicles, that is accessible and safe for everyone. To accomplish our aim, we came up with two designs and made them within the CAD software SolidWorks. The two different designs can be seen below on the second page, labeled Figure 1, they are a conveyor belt and a track system. They both allow a wheelchair user to be guided to a designated spot where they will be able to be locked down and secured within the vehicle without any outside help. The benefits of the conveyor system are that any wheelchair easily works with this, while some pros for the track system is that it can hold multiple wheelchairs at a time and will take up less power from the car to power the track then the conveyor belt.

Team Members: Aditya More, Sahil Powar, Brandon Scott, Nicholas Sexton

Faculty Advisor: Dr. Matthew Franchetti

Client Advisor: Ms. Jennifer Schlegel

Project Sponsor: DriveOhio

Special Thanks: Dr. Brain Trease for being an excellent professor for this course; Dr. Norman Rapino for helping us with our Technology Takes the Wheel presentation

The goal of this project was to build a heating and cooling stage for the testing of photovoltaic solar cells. This sample stage will then be integrated inside a chamber with solar emulating lights to mimic the characteristics of the sun. Measurements will then be taken of the power outputs of the solar cells analyzing their production as the temperature changes. The design specifications we were supposed to meet with the stage are:

- Temperature Range: -35°C to 60°C

- Temperature Uniformity in 4”x4” area: ±2°C

- Temperature Stability: ±1°C

These temperature requirements were to be achieved by using Peltier cooling modules supplemented by a recirculating heater/ chiller. The power outputs of the solar cells were to be measured using pogo pins protruding from the surface of the top of the copper plate. The copper plate also needed to be insulated from the bottom of the solar cell to prevent the cells from shorting out. Ease of Maintenace also had to be considered as component failure downtime had to be kept to a minimum. The project also had to be able to be controlled by LabView as that is the controller that was chosen for the whole project.

Team Members: Bilal Abdul Halim - Group Leader; Jacob Kennedy - Technical Liaison/Web Page Specialist; James Smith - Purchasing Agent; Jarod Michalak – Communications

Client advisor and project sponsor: Dr. Randall J. Ellingson – UT Physics Department

Faculty Advisor: Dr. Nicoleta Ene

Special Thanks: Brian Combs and Tim Grivanos – UT Machine shop; Dr. Randall J. Ellingson; Dr. Nicoleta Ene; Ebin Bastola; Dave Raker; UT Formula SAE Team

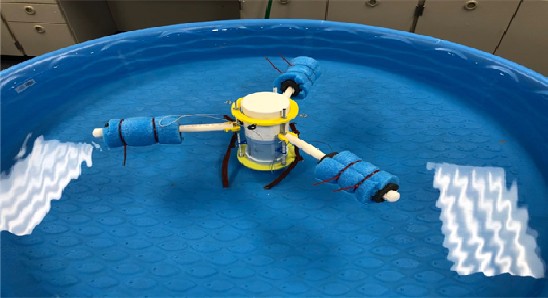

This group worked to develop a low-cost and robust way to quantify algal surface scum with the thought in mind that the technology will be distributed to users

all over the Great Lakes. This will provide essential data when reporting the appearance of algal blooms. Over the course of the semester, the team members brainstormed many ideas, but ultimately

developed and created a vertical capture system. 3D printing and standard store-bought materials were utilized to create an inexpensive mechanism. Additionally, through experimentation in a controlled environment,

the system proved to capture an accurate sample, which means that the Lake Erie Center

will have reliable samples to analyze.

This group worked to develop a low-cost and robust way to quantify algal surface scum with the thought in mind that the technology will be distributed to users

all over the Great Lakes. This will provide essential data when reporting the appearance of algal blooms. Over the course of the semester, the team members brainstormed many ideas, but ultimately

developed and created a vertical capture system. 3D printing and standard store-bought materials were utilized to create an inexpensive mechanism. Additionally, through experimentation in a controlled environment,

the system proved to capture an accurate sample, which means that the Lake Erie Center

will have reliable samples to analyze.

Team Members: Chris Blazevich, Lucas Wallace, Nathan Reithman, Levi Woerner, and Owen Hoover.

Faculty Advisor: Dr. Adam Schroeder

Client Advisor: Dr. Tom Bridgeman

Project Sponsor: Lake Erie Center and The University of Toledo

Special Thanks: Dr. Trease

Our senior design project was to construct an improved hovercraft for Imagination

Station. They plan on using it as a way to promote themselves as well as to educate young children in the fields of science

and engineering. Their current model had many limitations with steering, control,

weight capacity, surface compatibility, and runtime. Our project was meant to improve

upon all of these characteristics by designing a more stable and functional hovercraft model.

Throughout the semester we designed a hovercraft using three electrically ducted fans

for lift and two for thrust. The base was constructed of ¼” aluminum and was in the

shape of a hockey puck. The three lift fans build up pressure in an inner tube which

allows the craft to “hover” off the ground. The two thrust fans are able to rotate to a forward, neutral, and reverse position allowing for zero-turn capabilities.

The entire theme of the hovercraft was hockey as a partnership with the Toledo Walleye

allows Imagination Station to race during the intermission breaks between periods

at the hockey games.

Our senior design project was to construct an improved hovercraft for Imagination

Station. They plan on using it as a way to promote themselves as well as to educate young children in the fields of science

and engineering. Their current model had many limitations with steering, control,

weight capacity, surface compatibility, and runtime. Our project was meant to improve

upon all of these characteristics by designing a more stable and functional hovercraft model.

Throughout the semester we designed a hovercraft using three electrically ducted fans

for lift and two for thrust. The base was constructed of ¼” aluminum and was in the

shape of a hockey puck. The three lift fans build up pressure in an inner tube which

allows the craft to “hover” off the ground. The two thrust fans are able to rotate to a forward, neutral, and reverse position allowing for zero-turn capabilities.

The entire theme of the hovercraft was hockey as a partnership with the Toledo Walleye

allows Imagination Station to race during the intermission breaks between periods

at the hockey games.

Team Members: Trent Hensel, Khaled Mohamed, Luis De la Vega Gonzalez, Nathan Wingate, Andrew Markley

Faculty Advisor: Dr. Sorin Cioc

Client Advisor: Carl Nelson

Project Sponsor: Imagination Station

Special Thanks: University of Toledo Machine Shop

Sponsored by the University of Toledo Facilities and Construction department, the

purpose of this project was to find improvements for the main campus boiler system

located under Savage Arena. The project consisted of researching and evaluating the

boiler units to estimate their remaining lifespan as well as examining the supplemental

system surrounding it to identify issues and propose possible improvements. After

gaining an understanding of the workings of the system, the project team scheduled

and met with various equipment vendors to discuss improvement ideas and obtain quotes

for repairs. Given the price of the repairs, calculations were made to each possible

improvement’s possible operational cost savings and return on investment period. By

completing these objectives, the University of Toledo was given a calculated path

forward for improving the efficiency of the boiler system.

Sponsored by the University of Toledo Facilities and Construction department, the

purpose of this project was to find improvements for the main campus boiler system

located under Savage Arena. The project consisted of researching and evaluating the

boiler units to estimate their remaining lifespan as well as examining the supplemental

system surrounding it to identify issues and propose possible improvements. After

gaining an understanding of the workings of the system, the project team scheduled

and met with various equipment vendors to discuss improvement ideas and obtain quotes

for repairs. Given the price of the repairs, calculations were made to each possible

improvement’s possible operational cost savings and return on investment period. By

completing these objectives, the University of Toledo was given a calculated path

forward for improving the efficiency of the boiler system.

Team Members: Derek Corey-Goodman, Andrew Truitt, Nathan Kremer, Robert Connor, Matthew Limberg

Team Members: Derek Corey-Goodman, Andrew Truitt, Nathan Kremer, Robert Connor, Matthew Limberg

Faculty Advisor: Dr. Anju Gupta

Client Advisor: Michael Green

Project Sponsor: UT Facilities and Construction

Special Thanks: Brian Zieber of Energy Control, Joe McMullen of Thermogenics, and Boilerroom Equipment Inc.

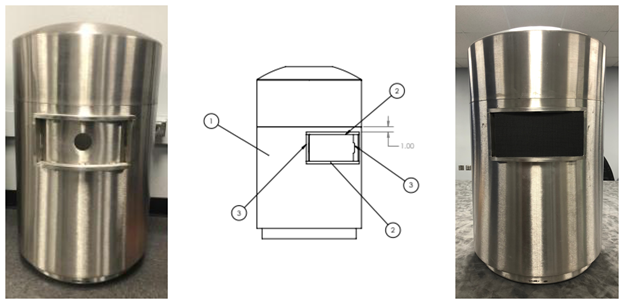

What basic item can be found in nearly every room? A waste receptacle. The potential

to use such a common item as an avenue to earn revenue through advertisements is the

basis for our project. The goal of the project is to take Toledo Metal Spinning’s

most popular waste receptacle model, the Cleanline, and integrate a flexible LED screen into it. The screen will have the potential

to display words, images or even full commercials. The design must be easily integrated

into Toledo Metal Spinning’s current manufacturing processes while also being able

to easily attach the screen to existing waste receptacles that have been purchased

by current customers.

What basic item can be found in nearly every room? A waste receptacle. The potential

to use such a common item as an avenue to earn revenue through advertisements is the

basis for our project. The goal of the project is to take Toledo Metal Spinning’s

most popular waste receptacle model, the Cleanline, and integrate a flexible LED screen into it. The screen will have the potential

to display words, images or even full commercials. The design must be easily integrated

into Toledo Metal Spinning’s current manufacturing processes while also being able

to easily attach the screen to existing waste receptacles that have been purchased

by current customers.

Team Members: Shubham Mahagaonkar - Team Leader; River Redman - Technical Liaison; Hayden Jean - Purchasing Agent; Dean Miller - Communications; Michael Tansey - Support Specialist

Team Members: Shubham Mahagaonkar - Team Leader; River Redman - Technical Liaison; Hayden Jean - Purchasing Agent; Dean Miller - Communications; Michael Tansey - Support Specialist

Faculty Advisor: Dr. Trease

Client Advisor: Eric Fankhauser

Project Sponsor: Toledo Metal Spinning

Special Thanks: Dr. Katy Johnson, Dr. Adam Schroeder

The main goal of this project was to design an effective and user-friendly device

to make the observation of woodpecker nests easier and less time-consuming. The device

needs to be able to be used repeatedly and needs to be somewhat easily reproduced.

While scaring the woodpeckers away from the nest temporarily is not a concern, damaging

the eggs inside the nest is, so safety in that regard needs to be taken into consideration.

The device must also be able to support a camera and hold the camera steady enough

to capture an image. The device must be convenient and light-weight enough for a drone

to lift and maneuver it through tree branches, to heights of 60+ feet, and into the

hole for a woodpecker nest for observation.

The main goal of this project was to design an effective and user-friendly device

to make the observation of woodpecker nests easier and less time-consuming. The device

needs to be able to be used repeatedly and needs to be somewhat easily reproduced.

While scaring the woodpeckers away from the nest temporarily is not a concern, damaging

the eggs inside the nest is, so safety in that regard needs to be taken into consideration.

The device must also be able to support a camera and hold the camera steady enough

to capture an image. The device must be convenient and light-weight enough for a drone

to lift and maneuver it through tree branches, to heights of 60+ feet, and into the

hole for a woodpecker nest for observation.

Team Members: Rachel Doctor, Jonathon Lesicki, Thomas Friar, Zachary Plotts

Faculty Advisor: Dr. Adam Schroeder

Client Advisor: Dr. Richard Becker

Client: Dr. Henry Streby

Project Sponsors: University of Toledo, AJD Racing

Special Thanks: University of Toledo AJD Racing Dr. Becker and Dr. Streby

Dana Incorporated was looking for a better way to store and transport the components

of Universal Joints. They are currently using temporary trays and bags for storage

and transportation. They need a container to store and transport these components

after testing and want the container to be as small and compact as possible while

keeping components organized. This would be an improvement on the current storage

method and enable easier long-term storage and transportation. Initially, four designs were created to create different concepts for how to store

the components. After reviewing the initial designs, the preferred design elements from each initial

design were used to create a new design. This new design includes an individual slot for each component with the exception of the roller bearings which will be stored within plastic bags in the bearing cups. To ensure the final design was fit for use, prototypes were tested by conducting a drop test, backpack transportation test, lid fatigue test, and a compression test. The final

design passed all testing and satisfied the requirements for the project. It has also been approved by representatives

of Dana Incorporated and is being implemented to replace past storage methods.

Dana Incorporated was looking for a better way to store and transport the components

of Universal Joints. They are currently using temporary trays and bags for storage

and transportation. They need a container to store and transport these components

after testing and want the container to be as small and compact as possible while

keeping components organized. This would be an improvement on the current storage

method and enable easier long-term storage and transportation. Initially, four designs were created to create different concepts for how to store

the components. After reviewing the initial designs, the preferred design elements from each initial

design were used to create a new design. This new design includes an individual slot for each component with the exception of the roller bearings which will be stored within plastic bags in the bearing cups. To ensure the final design was fit for use, prototypes were tested by conducting a drop test, backpack transportation test, lid fatigue test, and a compression test. The final

design passed all testing and satisfied the requirements for the project. It has also been approved by representatives

of Dana Incorporated and is being implemented to replace past storage methods.

Team Members: Ibrahim Alayidi - Team Leader; Matt Truesdell - Technical Liaison, Product Testing; Chris Samonides - Technical Liaison, 3D Printing; Cameron Forsythe - Reporting and Documentation Specialist

Team Members: Ibrahim Alayidi - Team Leader; Matt Truesdell - Technical Liaison, Product Testing; Chris Samonides - Technical Liaison, 3D Printing; Cameron Forsythe - Reporting and Documentation Specialist

Faculty Advisor: Dr. Meysam Haghshenas

Client Advisor: Kyle Albertson, Cody Ott, Denny Costin, and Mark Sundstrom

Project Sponsor: Dana Incorporated, The University of Toledo

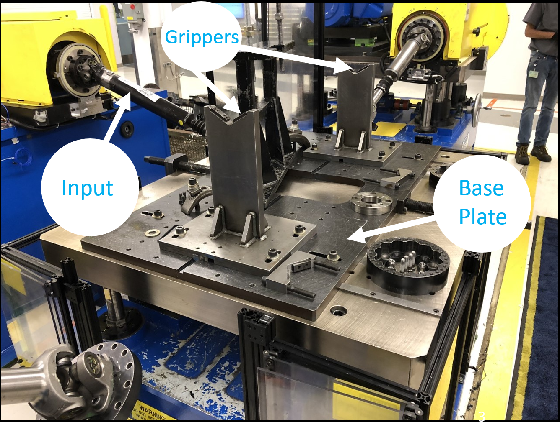

A few of the axles that Dana manufactures are tested in the NVH Lab. NVH (Noise, Vibration,

Harshness) testing involves subjecting a full vehicle, component or subassembly to vibrations

at different frequencies, as a means of determining mode shapes and isolating buzzes,

squeaks, and rattles. In the lab there are two machines, the “Joko” and the “Beast”, they both have the

same job but the Joko tests with a max torque of 350 Nm where the “Beast” tests with

a max torque of 3,000 Nm. We were to focus on a test fixture for the “Beast”. During

testing because of the high input torque, the axle wants to rotate out of the fixture.

This incident has happened once before and the machine was damaged and no one was

hurt, but because of this, they had installed a fixture around the differential that

makes it difficult when changing out the axles. We designed a fixture to eliminate the fixture on the differential that would, in turn,

make for quicker change out time and better grip on the axle during testing.

A few of the axles that Dana manufactures are tested in the NVH Lab. NVH (Noise, Vibration,

Harshness) testing involves subjecting a full vehicle, component or subassembly to vibrations

at different frequencies, as a means of determining mode shapes and isolating buzzes,

squeaks, and rattles. In the lab there are two machines, the “Joko” and the “Beast”, they both have the

same job but the Joko tests with a max torque of 350 Nm where the “Beast” tests with

a max torque of 3,000 Nm. We were to focus on a test fixture for the “Beast”. During

testing because of the high input torque, the axle wants to rotate out of the fixture.

This incident has happened once before and the machine was damaged and no one was

hurt, but because of this, they had installed a fixture around the differential that

makes it difficult when changing out the axles. We designed a fixture to eliminate the fixture on the differential that would, in turn,

make for quicker change out time and better grip on the axle during testing.

Team Members: Mark DeNucci, Toni Carrion, Jaber Aljadah, Brandon Hensley

Faculty Advisor: Hongyan Zhang

Client Advisor: Sruthi Madala

Project Sponsor: Dana, Inc

Special Thanks: Dr. Trease, NVH team at Dana, and Dr. Hong

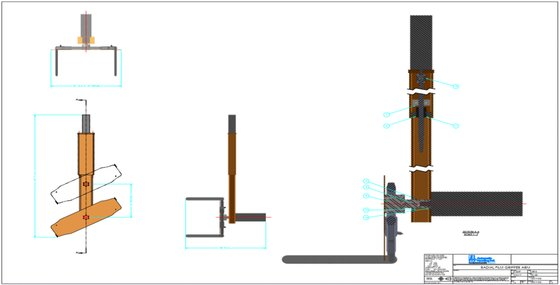

Automatic Handling International (AHI) provides automated systems for roll handling

and pulp handling. We were assigned to provide a method for their radial wrapping

portion of their systems to where it does not use any consumables, such as glue, to

adhere to plastic for packaging. The reasoning for this transition is to provide their

customers with an alternative method that would be less money for them to operate

in the long run and that wouldn’t result in a loss of productivity that comes from

the use of consumables. The solution that we supplied to AHI was that of a mechanical

revolving arm that holds down plastic wrap against the roll for one revolution. This

method results in plastic form-fitted against the roll, but with a cling adherence

between the plastic wrap layers from the overlapping of the first revolution.

Automatic Handling International (AHI) provides automated systems for roll handling

and pulp handling. We were assigned to provide a method for their radial wrapping

portion of their systems to where it does not use any consumables, such as glue, to

adhere to plastic for packaging. The reasoning for this transition is to provide their

customers with an alternative method that would be less money for them to operate

in the long run and that wouldn’t result in a loss of productivity that comes from

the use of consumables. The solution that we supplied to AHI was that of a mechanical

revolving arm that holds down plastic wrap against the roll for one revolution. This

method results in plastic form-fitted against the roll, but with a cling adherence

between the plastic wrap layers from the overlapping of the first revolution.

Team Members: Jordan Evanski, Jordan Shepler, Christopher Collins, Nicholas Hicks

Team Members: Jordan Evanski, Jordan Shepler, Christopher Collins, Nicholas Hicks

Faculty Advisor: Dr. Anju Gupta

Client Advisor: Ralph Dylkowski

Project Sponsor: Automatic Handling International

Special Thanks: Dr. Brian Trease

The objective of this project is to design, analyze, and test a mechanism that could

help our client, Joel, achieve more motion while living with muscular dystrophy. The mechanism will be used to give our client an improved ability to raise, retract,

and rotate his left arm. This will allow him to make larger gestures, and be more expressive on stage, along with potentially helping

in day to day activities.

The objective of this project is to design, analyze, and test a mechanism that could

help our client, Joel, achieve more motion while living with muscular dystrophy. The mechanism will be used to give our client an improved ability to raise, retract,

and rotate his left arm. This will allow him to make larger gestures, and be more expressive on stage, along with potentially helping

in day to day activities.

By utilizing video chat, we were able to come up with a design, create it using rapid prototype 3D printing, and ship our client a finished prototype. After trying the physical prototype for the first time, Joel was thrilled with the results and provided us with valuable feedback for further revisions. Another revision is planned to be shipped to him, and all documentation will be handed on to Dr. Trease and hopefully another senior design group in the following semester.

Team Members: Brandon Payeff, Cassandra Brown, Nicholas Wryst, Adam Pusateri

Faculty Advisor: Brian Trease

Client Advisor: Matt Foss

Project Sponsor: The Roy and Marcia Armes Engineering Leadership Institute, University of Toledo - College of Engineering - Mechanical Engineering Department, Matthew Foss- University of Toledo Department of Theatre and Film

Special Thanks: AJD Racing, Nicholas Michael

Our client, Dr. Kim Anderson, lives near Cleveland, OH where she moved in 2018. She

uses an electric wheelchair to get around due to her spinal cord injury. She currently

has a wheelchair ramp in her front yard to access and enter the front door of her

house. Snow and rain cause concern with the electric-powered wheelchair, such as moisture-induced failure of her wheelchair and slippery conditions.

Our client, Dr. Kim Anderson, lives near Cleveland, OH where she moved in 2018. She

uses an electric wheelchair to get around due to her spinal cord injury. She currently

has a wheelchair ramp in her front yard to access and enter the front door of her

house. Snow and rain cause concern with the electric-powered wheelchair, such as moisture-induced failure of her wheelchair and slippery conditions.

To solve this problem, we want to place a wheelchair lift in the hallway of her garage, so she can enter her house from inside. This would allow her to get out of the elements and she won’t have to worry about any snow or ice. We want to design a type of wheelchair lift that can convert into steps while not in use. This would allow others living in the house to access the house through the stairs in the garage.

Team Members: Nick Streacker, Samer Obeid, Isaac Hutchison, Tom Shepherd

Faculty Advisor: Dr. Mohamed Samir Hefzy

Client Advisor: Dr. Kim Anderson

Project Sponsor: The University of Toledo

Special Thanks: John Jaegly and MIME Shop, Tom Koenig

The Pratt & Whitney R4360 Aircraft Engine was introduced in the 1940s. An aircraft enthusiast generously donated this engine to the University of Toledo to be restored. This semester, fall 2019, is the 8th semester, and team, to work on this engine. The project was received with little documentation, which presented issues. The University of Toledo was also doing construction in the engine lab, where the engine is located, preventing work from being done on the engine. It was then decided to design and build a starter stand to test the starters and in the future connect to the engine itself to control it.

Team Members: Adam Beroske, Justan May, Anthony McBride, Hannah Saunders

Faculty and Client Advisor: Dr. D. Ray Hixon

Project Sponsor: The University of Toledo

Special Thanks: The University of Toledo, Kevin Cameron, Graham White

Our team was tasked with designing two different components for our project. The two components we have designed for our project include a pallet and end of arm tooling. The pallet will be mounted to a moving conveyor on the assembly line. The requirements of the pallet is to be able to hold both top load and front load washing machine tubs, it must be able to hold both tubs in two different orientations and it must be able to rotate for assembly purposes. The end of arm tooling will be mounted to a Fanuc M710 robot. The purpose of this end of arm tooling is to grip the tubs and flip them for assembly purposes. The requirements of this tooling are to be able to grip both styles of tubs and flip them and the tooling has to weigh under 22 lbs due to the robot’s 110 lbs lifting restriction.

Team Members: Matthew Boyer - Group Leader, Purchasing Agent; Callie Brandt - Communication Specialist; Zachary Floriana - Technical Liaison; Jacob Henderson - Technical Liaison

Faculty Advisor: Dr. Ala Qattawi

Client Advisor: Doug Burns

Project Sponsor: Whirlpool Corporation

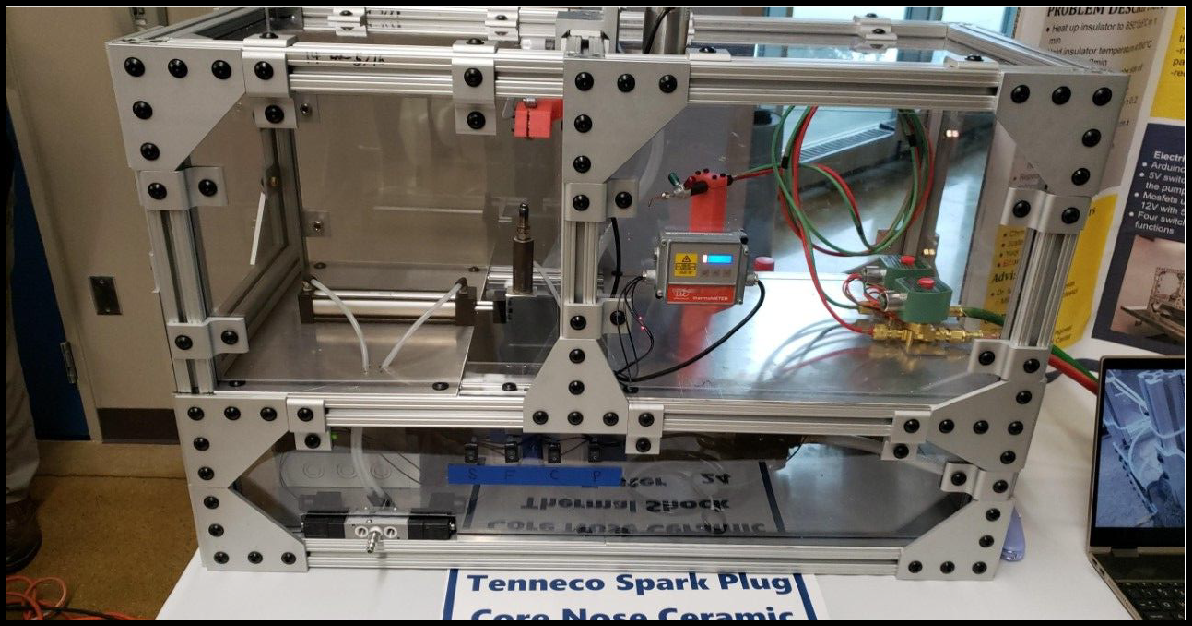

Our project is a thermal shock tester for the core nose of a spark plug. This is the

end of the spark plug that resides in the combustion chamber of an engine. This test

stand is used to heat and quench a spark plug to test the strength of the ceramic

during a thermal shock. Tenneco Powertrain is the sponsor of this project. Our design

uses a propane-oxygen torch that is capable of heating the spark plug to 850 degrees

Celcius. It also includes a pump system running through a 3/8 inch hose to a .07 inch

nozzle to quench the part. There is also an actuator that will shift the part between

each system. The process then cycles five times before completion.

Our project is a thermal shock tester for the core nose of a spark plug. This is the

end of the spark plug that resides in the combustion chamber of an engine. This test

stand is used to heat and quench a spark plug to test the strength of the ceramic

during a thermal shock. Tenneco Powertrain is the sponsor of this project. Our design

uses a propane-oxygen torch that is capable of heating the spark plug to 850 degrees

Celcius. It also includes a pump system running through a 3/8 inch hose to a .07 inch

nozzle to quench the part. There is also an actuator that will shift the part between

each system. The process then cycles five times before completion.

Team Members: Yuqi Chen, Justen Garmenn, Christopher Kos, Ethan Nye

Team Members: Yuqi Chen, Justen Garmenn, Christopher Kos, Ethan Nye

Faculty Adviosr: Dr. Meysam Haghshenas

Client Advisor: Chandler Noirot

Project Sponsor: Tenneco Powertrain

The objective of this project is to assess, analyze, and document Therma-Tru’s TT205W

Water and Air infiltration testing procedure to determine the root causes of variance

in results. This project is being completed to provide higher consistency of data

produced from this procedure so that the Therma-Tru engineering team can conduct engineering

changes and decisions with a higher level of confidence. In order to better understand

this entire process, our team will observe 12 individual door systems built to completion

while also observing 2 tests to be conducted on each of those systems, resulting in

24 observed tests. Our team will compare the results to the observations noted when

watching each system build in order to determine which variables affected the system.

A process map will be created for each system built and a testing sheet will be completed

for each test observed. When our team has completed observing all 12 system builds

and 24 testing procedures, we will develop a table of conclusions to be given to Therma-Tru

that highlights which variables have the largest impact on the results of the test

and to rank each variable by how much of an impact they have on the overall results.

The objective of this project is to assess, analyze, and document Therma-Tru’s TT205W

Water and Air infiltration testing procedure to determine the root causes of variance

in results. This project is being completed to provide higher consistency of data

produced from this procedure so that the Therma-Tru engineering team can conduct engineering

changes and decisions with a higher level of confidence. In order to better understand

this entire process, our team will observe 12 individual door systems built to completion

while also observing 2 tests to be conducted on each of those systems, resulting in

24 observed tests. Our team will compare the results to the observations noted when

watching each system build in order to determine which variables affected the system.

A process map will be created for each system built and a testing sheet will be completed

for each test observed. When our team has completed observing all 12 system builds

and 24 testing procedures, we will develop a table of conclusions to be given to Therma-Tru

that highlights which variables have the largest impact on the results of the test

and to rank each variable by how much of an impact they have on the overall results.

Team Members: Grant Harmon, Grant Zeller, Trent Pawleki, Seth Billings, Andrew Jolley

Faculty Advisor: Dr. Nicoleta Ene

Client Advisor: Salvador Galicia

Project Sponsor: Therma-Tru Corporation

Special Thanks: Connor Funk, John Hannon (Therma-Tru Technicians)