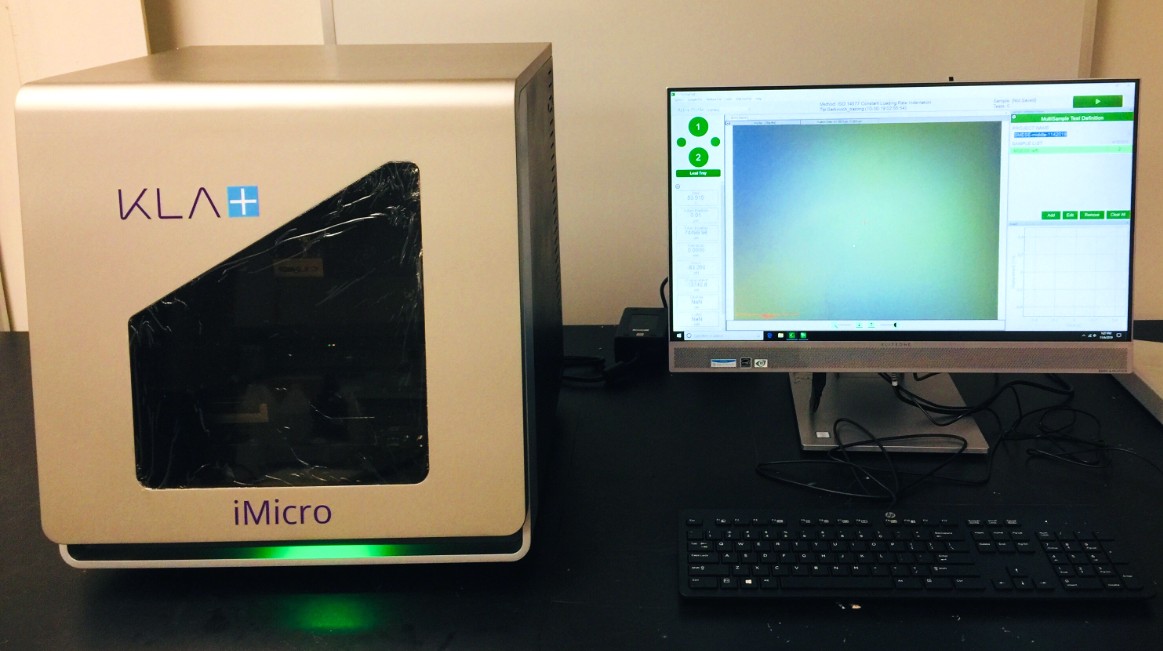

Facilities in the Micro/Nano-Mechanics Laboratory

Nanoindentation system

The iMicro (KLA+) Nanoindenter measures mechanical/tribological properties such as hardness, elastic modulus, friction,

adhesion, creep, fatigue, and damping down to sub-nm length scale. It can be used

to characterize nanostructures and bulk materials by conducting numerous measurements

rapidly and precisely (high-speed hardness mapping). The characterization follows

the ISO 14577 (ASTM E 2546) standard.

The iMicro (KLA+) Nanoindenter measures mechanical/tribological properties such as hardness, elastic modulus, friction,

adhesion, creep, fatigue, and damping down to sub-nm length scale. It can be used

to characterize nanostructures and bulk materials by conducting numerous measurements

rapidly and precisely (high-speed hardness mapping). The characterization follows

the ISO 14577 (ASTM E 2546) standard.

ISO/ASTM standard

The ISO 14577 (ASTM E 2546) method is used to measure the modulus and hardness of different materials. The nanoindentation experiments can be performed by controlling load, loading rate, displacement, and displacement rate among many other parameters. The choice of these parameters depends on the material type and application need. The ISO 14577 compliance has been set up by the National Institute of Standards and Technology as the standard method to qualify test methods, verification, and calibration of testing machines and calibration of reference blocks.

The process ensures that the instrument is performing up to the standards in surface contact determination, frame compliance, area function by indentation and calculations of the modulus (E) and hardness (H). The properties of the calibration samples are measured over 16 forces for the measurement accuracy of 0.1%.

Capabilities

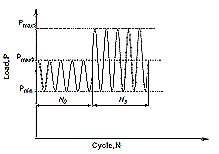

Indentation fatigue

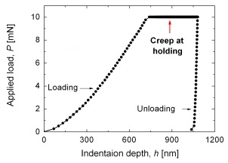

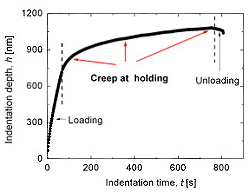

Indentation creep

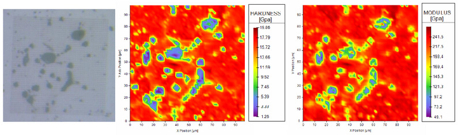

Hardness and modulus mapping

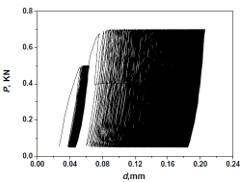

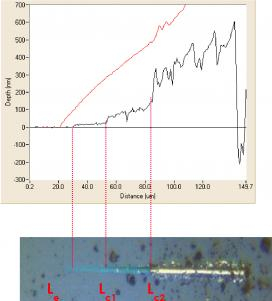

Wear (scratch testing)