Understanding Adjacent Box Beam Bridges and Their Evaluation

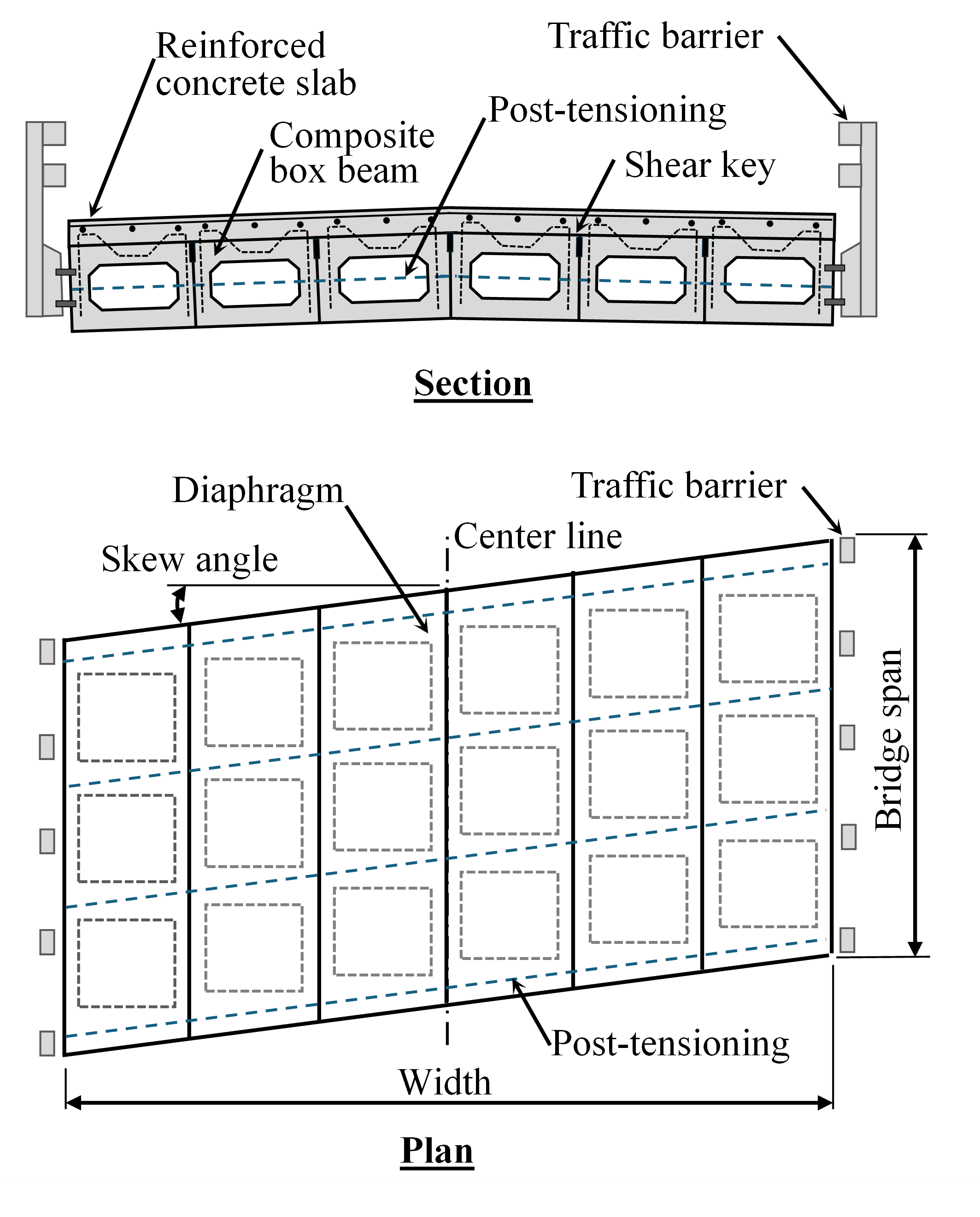

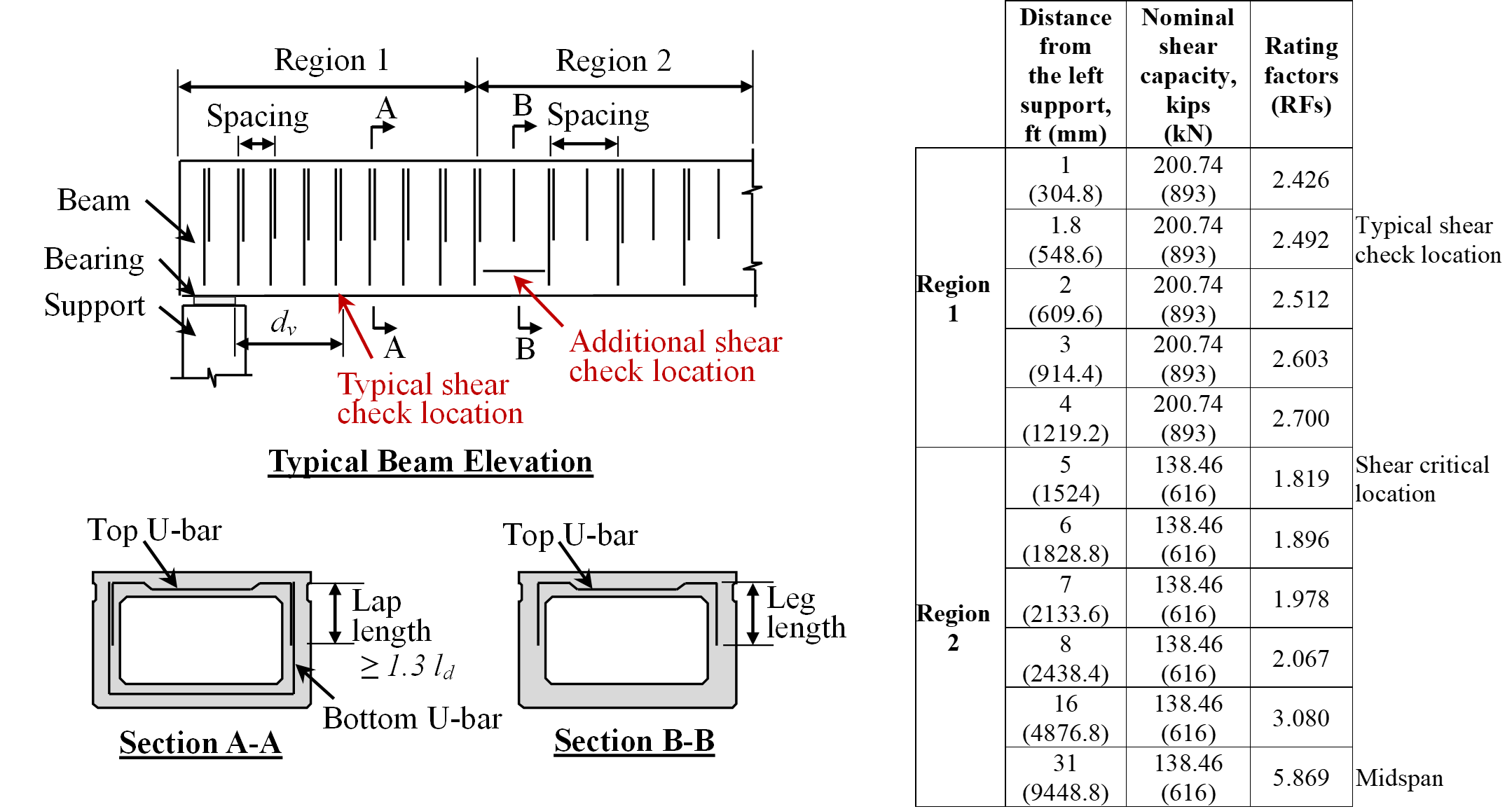

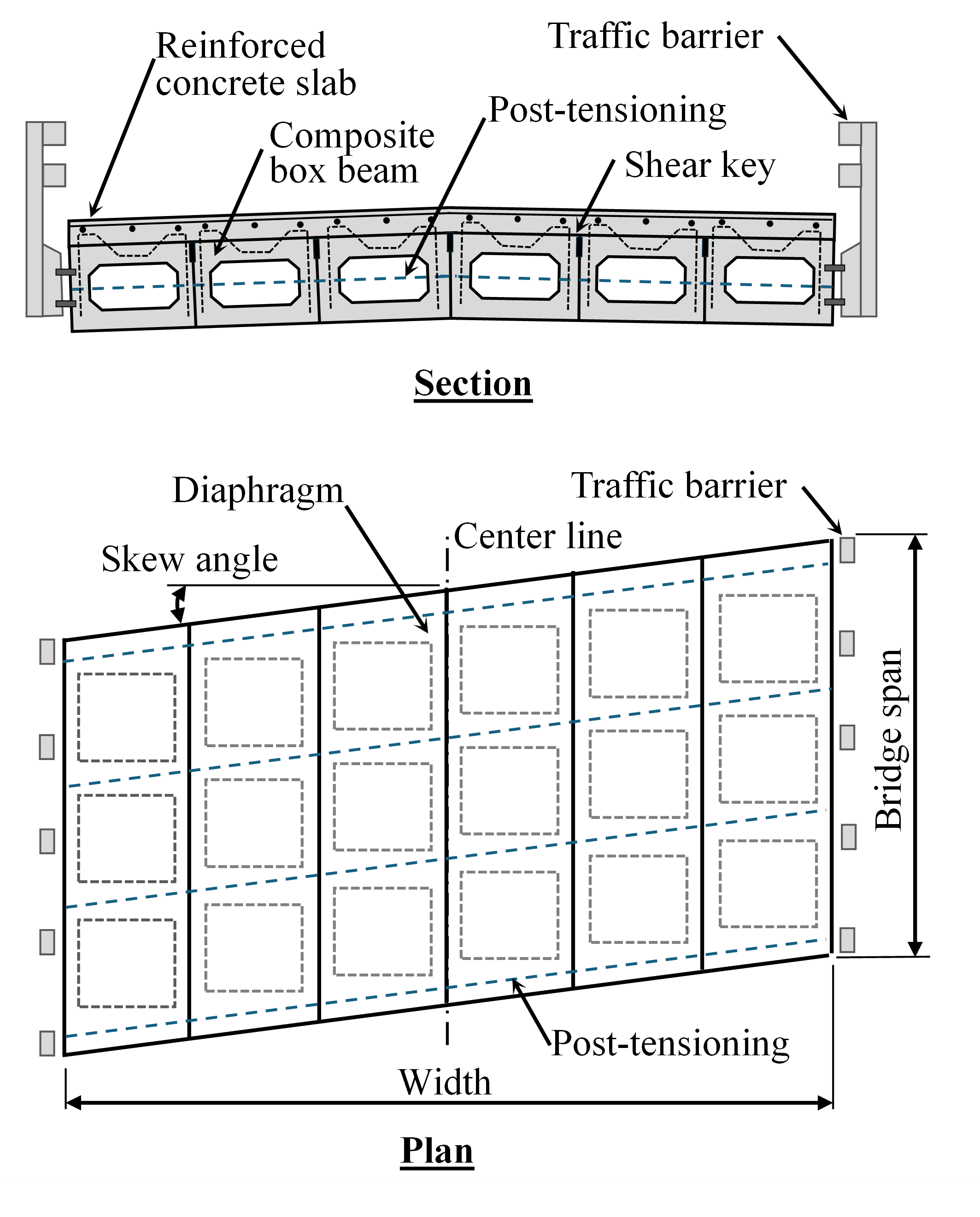

Precast, prestressed adjacent box beam bridges are a common and efficient bridge type. They're built by placing precast concrete

box beams side-by-side, then connecting them with shear keys and post-tensioning.

You can see this in the figure below. These bridges are typically simply supported,

and can be straight or skewed, with either composite or non-composite beams. They

make up a significant portion of the U.S. bridge inventory, for example, accounting

for 27% of Ohio's bridges. Primarily used for short to medium spans, box beam bridges

are favored for their excellent span-to-depth ratio, quick construction, and pleasing

appearance.

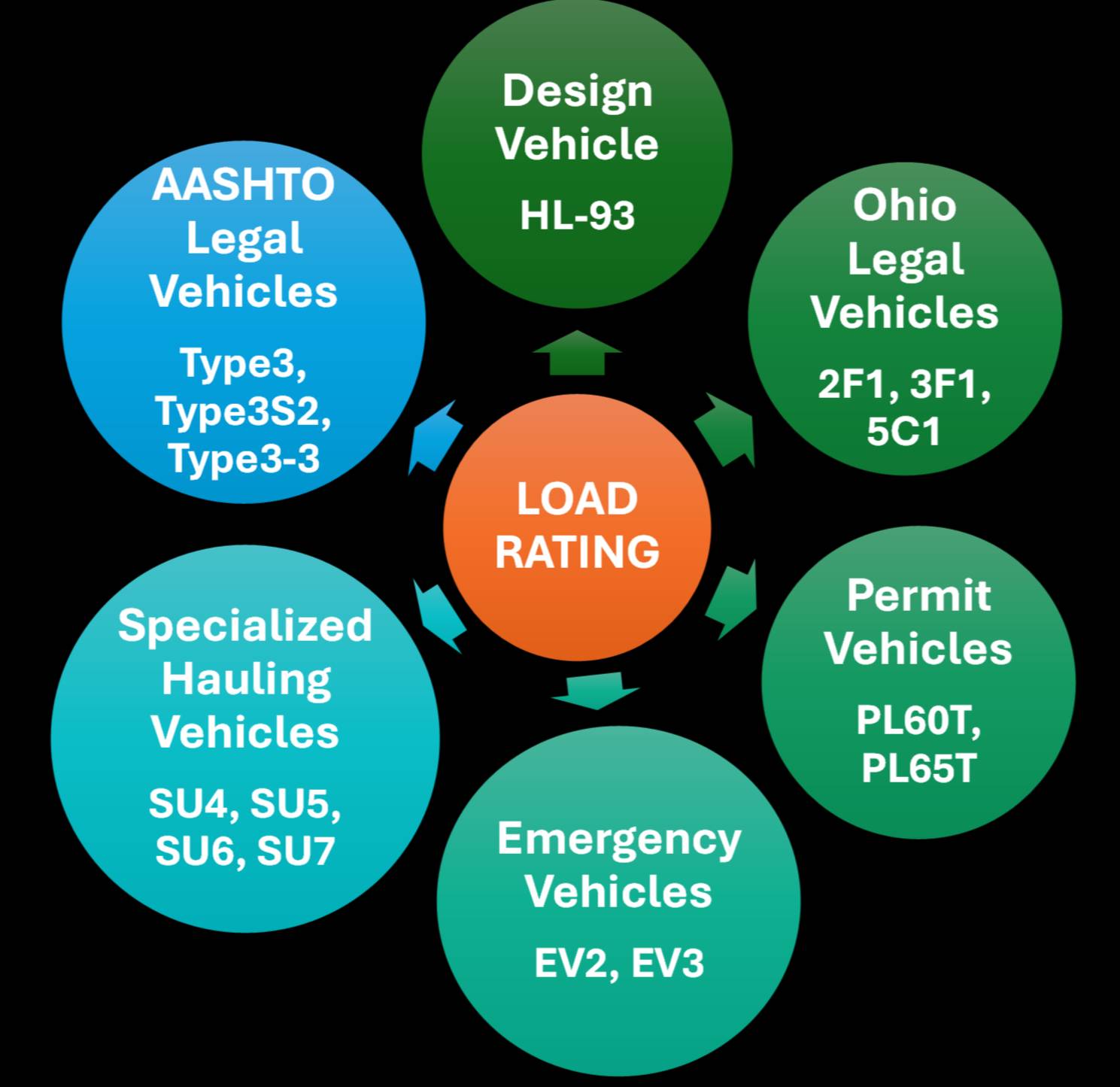

The Importance and Challenges of Bridge Load Rating

Bridge evaluation is a systematic process to assess a bridge's structural condition, load capacity,

and overall performance, ensuring it remains safe and serviceable under current and

future loads. A critical part of this is load rating, which determines a bridge's safe live load-carrying capacity based on its design

and site conditions. In fact, National Bridge Inspection Standards require all bridges

in the national inventory to be load rated.

However, load rating bridges, especially box beam types, presents several challenges.

Engineers must perform extensive calculations for various vehicle types, adhering

to multiple standards. Relying on hand calculations or general-purpose tools is often

complex and time-consuming due to the sheer number of box beam sections used historically

and the intricate calculations required for shear, flexure, and stress limits. Despite

the widespread use of adjacent box beam bridges, there's a notable gap in available

computational methods and automated tools for their specific load rating, compared

to other bridge types.

Introducing AD-BOX: A Solution for Efficient Load Rating

To overcome these challenges, we developed AD-BOX, an innovative computer tool designed for the accurate, reliable, and rapid load rating of adjacent box beam bridges. AD-BOX automates the entire process: it calculates loads, distribution factors,

bending moments, shear forces, and beam capacities based on your input, ultimately

generating the essential rating factors.

|

|

AD-BOX is specifically designed for the load rating of precast, prestressed adjacent box

beam bridges. It meticulously evaluates these structures using applicable limit states

under both inventory and operating conditions. For strength limit states, it employs

the load and resistance factor rating (LRFR) method, while for service limit states, it utilizes the allowable stress design (ASD) method.

AD-BOX offers comprehensive analysis capabilities, including:

-

Accounting for both skewed and non-skewed spans, with composite and non-composite

cross-sections.

-

Detailed analysis of flexure and shear.

-

Consideration of both single and multicell box beam sections.

-

Assessment of stresses at all potentially critical locations for strength and service

limit states.

-

Accurate capacity calculations.

-

Generation of final load rating factors.

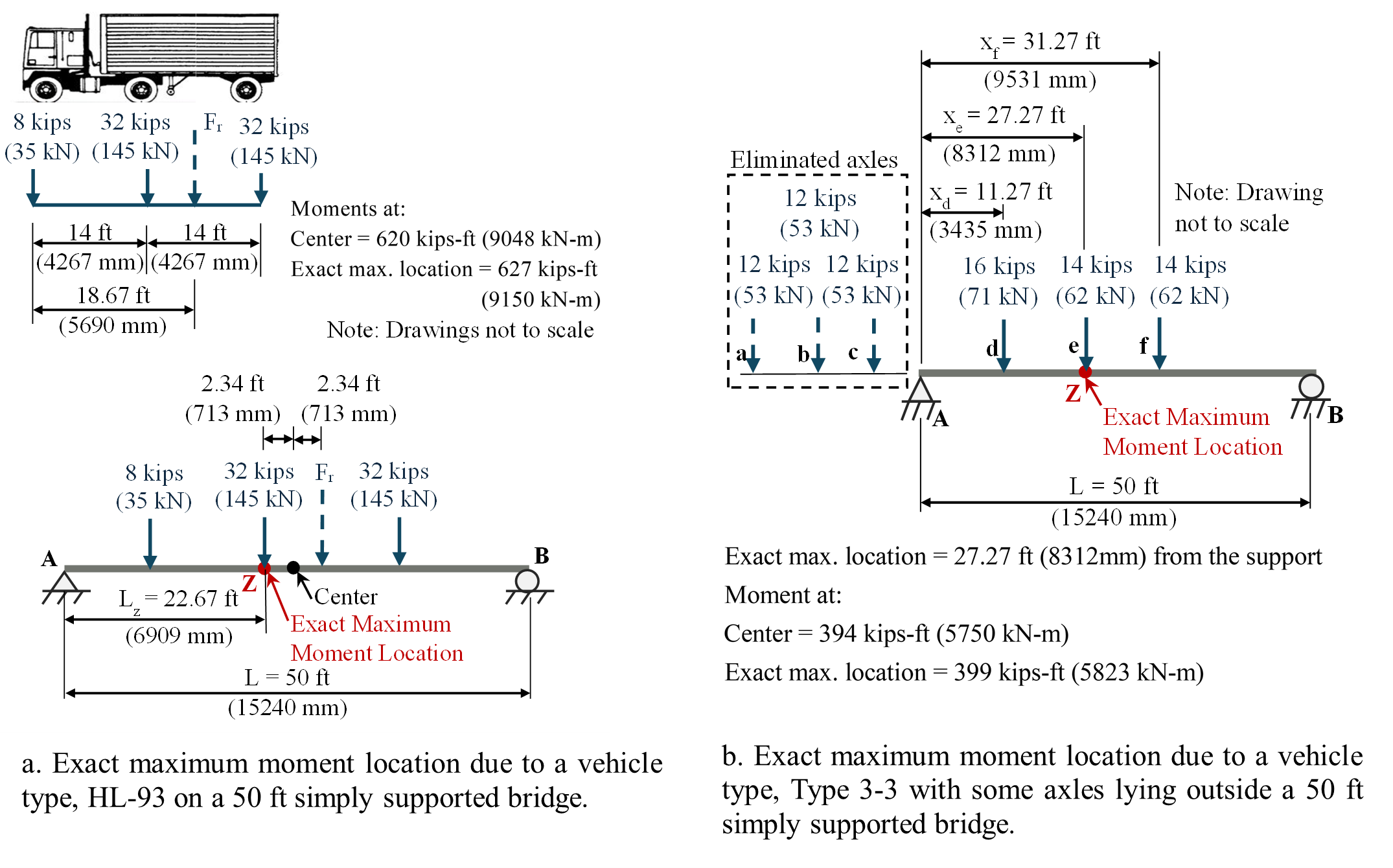

Enhanced Accuracy and Efficiency

A key feature of AD-BOX is its ability to precisely determine the critical location exhibiting the maximum load effect and the minimum rating factor. Unlike conventional

methods that might use a simplified one-tenth-of-the-span approach, AD-BOX calculates

the maximum moment capacity at the exact location of the maximum moment. This significantly improves accuracy, streamlines analysis output, and reduces engineering

effort.

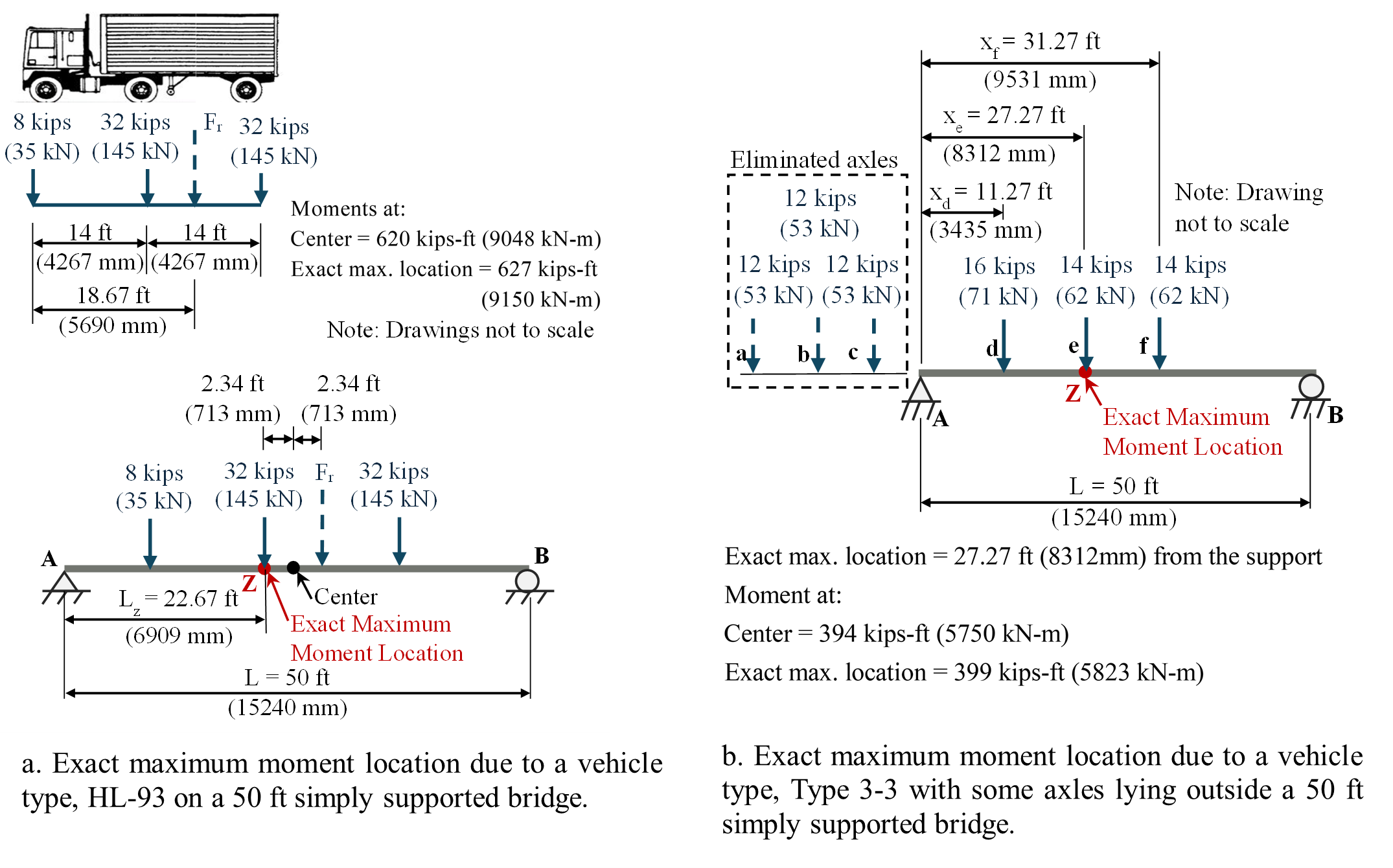

Furthermore, AD-BOX employs a specialized algorithm to tackle the challenge of determining

the exact maximum moment location for longer vehicles, especially when some axles

extend beyond the bridge span. This ensures only relevant axles within the span are

considered in calculations. The figure below illustrates how AD-BOX accurately identifies

the exact maximum moment location for different vehicle types on a simply supported

bridge.

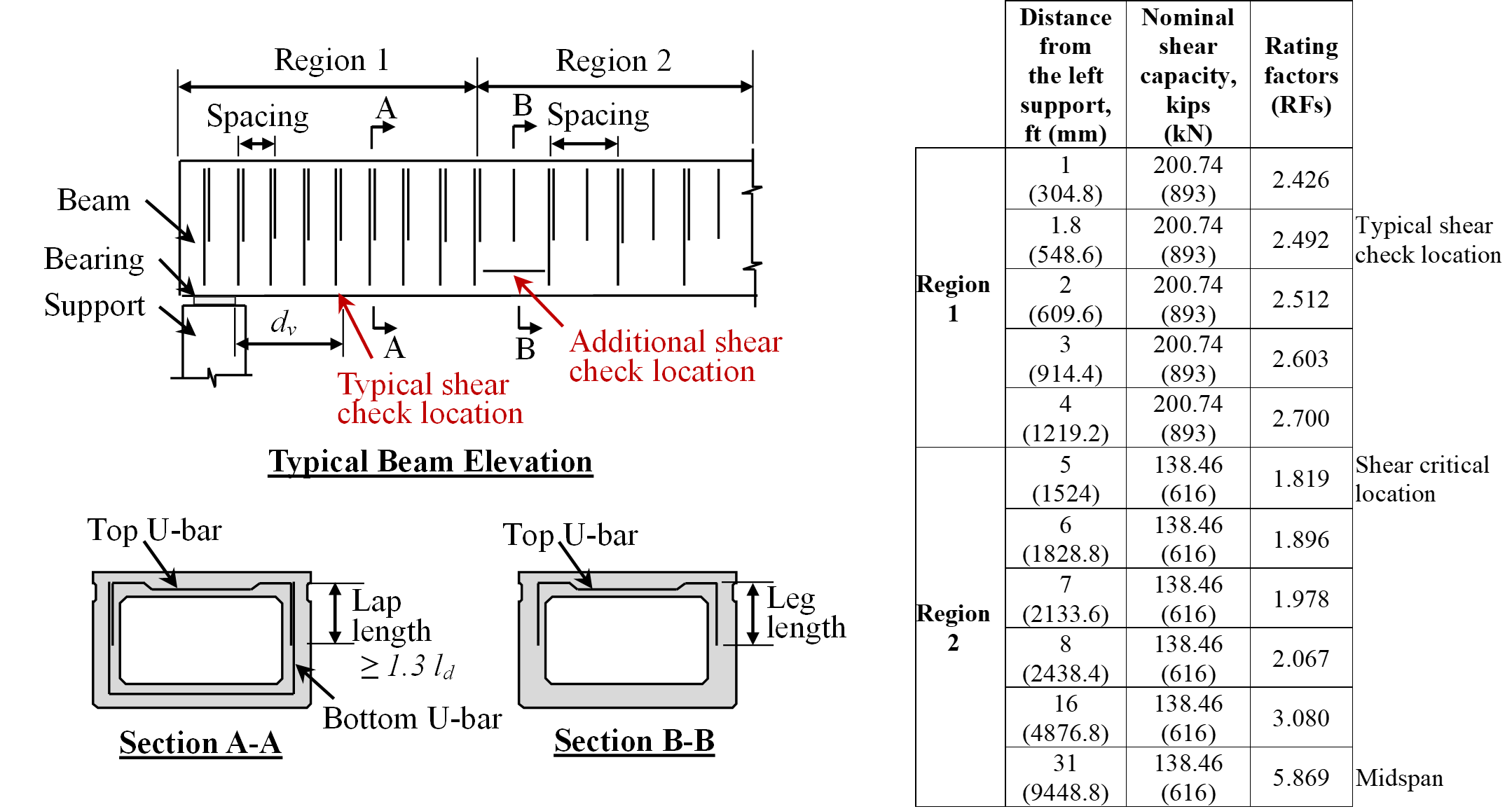

Comprehensive Shear Load Rating

AD-BOX evaluates shear load rating not just at typical shear-critical locations, but

also at other potentially critical points along the bridge. This is especially important where shear reinforcement details

or spacing might change. As illustrated in the figure below, the shear load rating

can often be more critical in "Region 2" (where shear reinforcement changes) than

at the conventionally assumed shear-critical section.

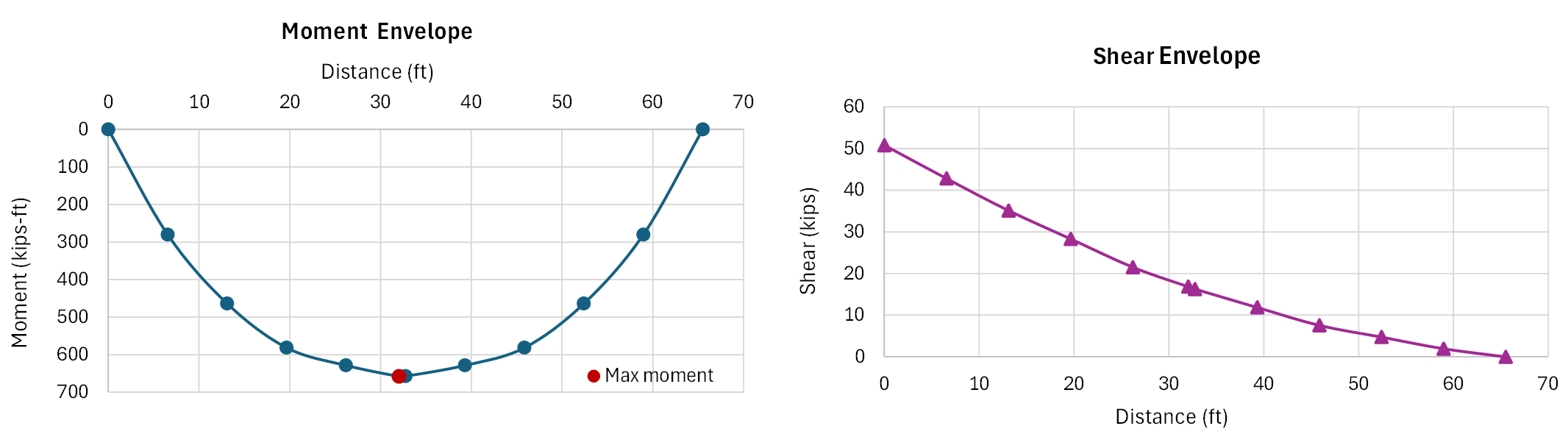

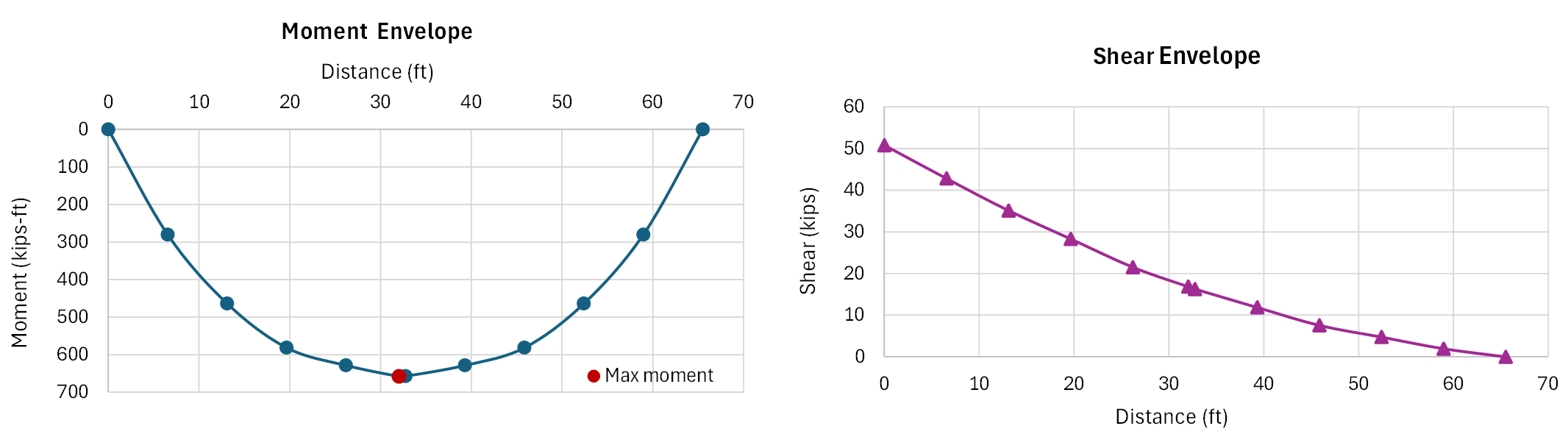

Versatile Moment and Shear Envelopes

To maximize the tool's utility for engineers working with any simply supported bridge,

AD-BOX includes an algorithm that generates moment and shear envelopes for all 15 standard vehicle types, as well as for extra-long custom vehicles. These

envelopes are provided in both tabular and chart formats. The tabular format allows engineers to easily copy values for use in other analysis

software or for independent hand calculations. The chart format, on the other hand,

offers a clear visual representation of the envelopes, highlighting their variation

along the span and precisely identifying peak values.

|

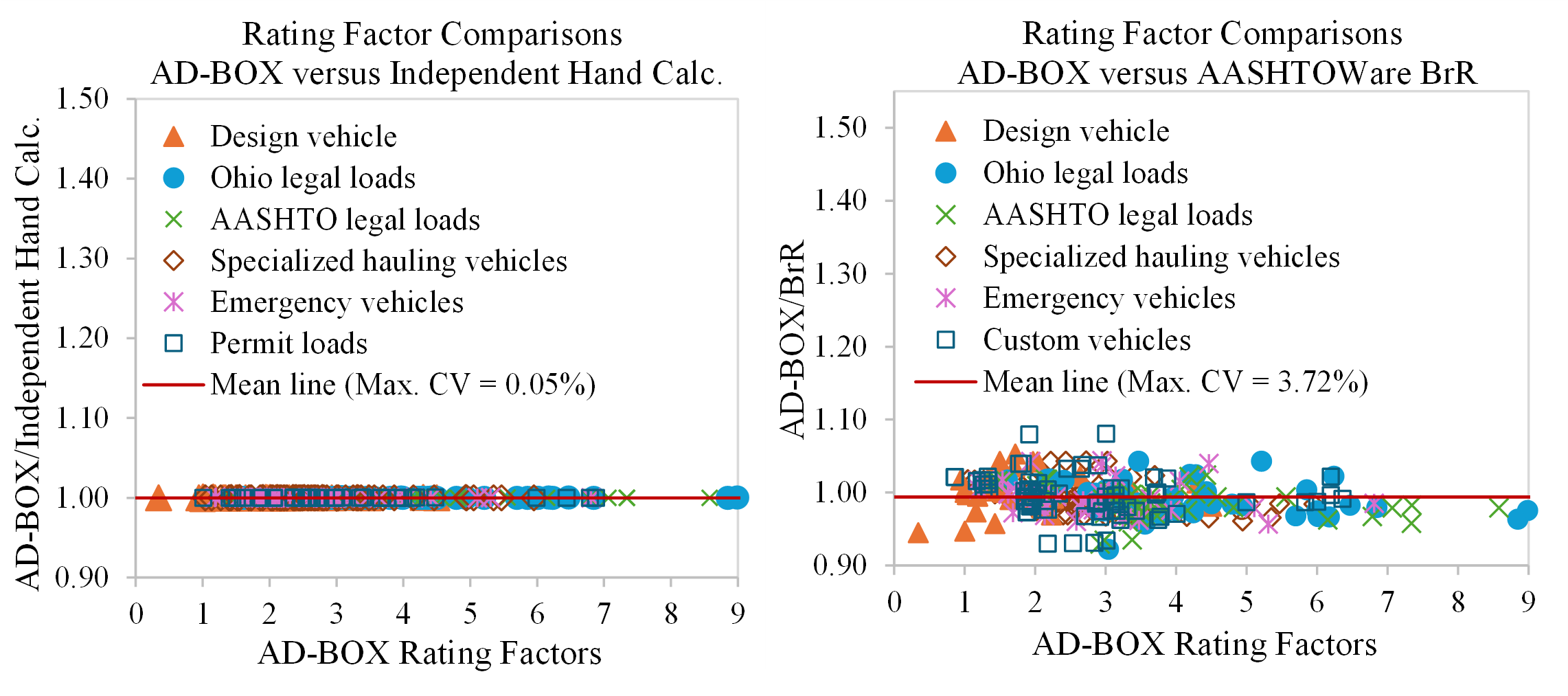

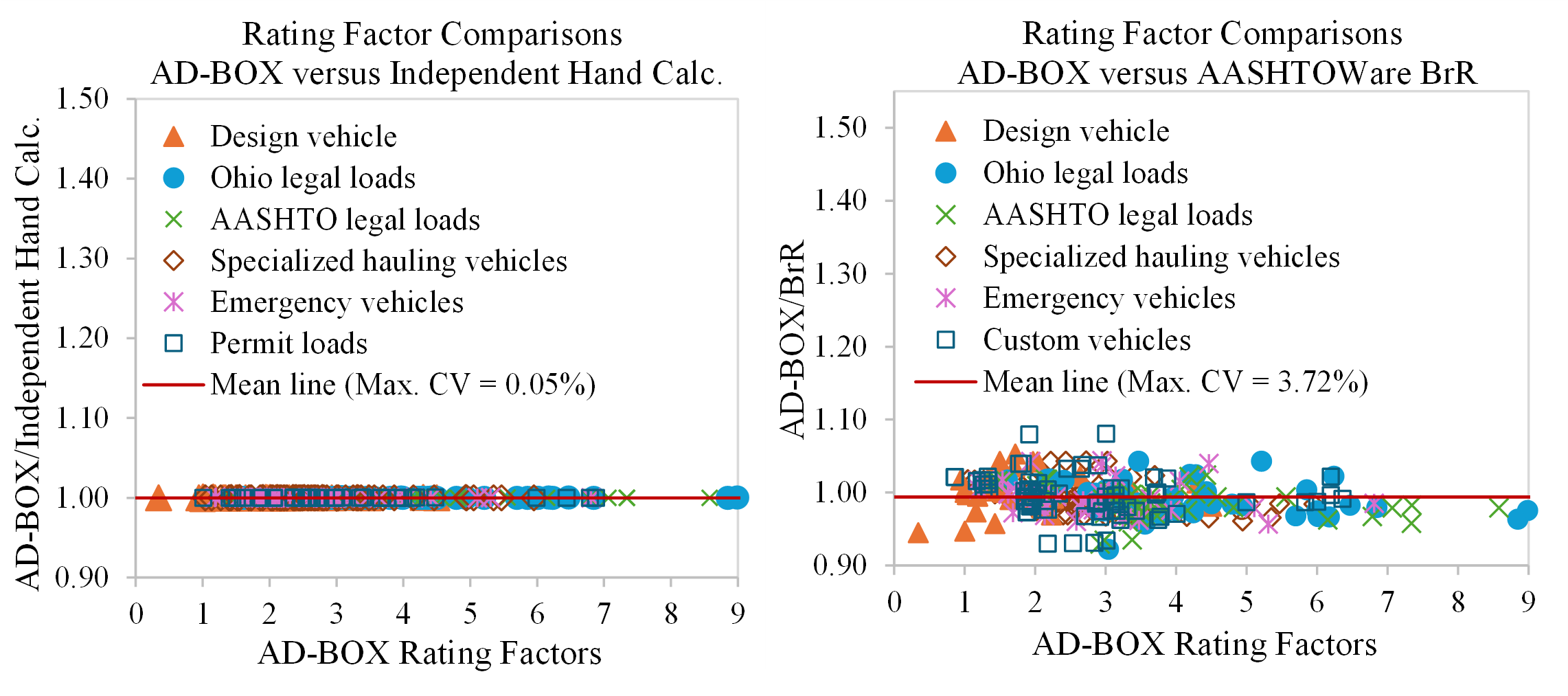

AD-BOX: Verified Accuracy and Reliability

The figure below showcases the rigorous verification and comparison studies conducted

on AD-BOX. We evaluated 18 bridges using 15 standard vehicle types and four custom vehicles (12, 15, 19, and 35 axles) to confirm the tool's performance.

Our verification studies, comparing AD-BOX results against independent hand calculations for the 15 standard vehicle types,

consistently yielded a mean rating factor (RF) ratio of nearly 1.0, with a coefficient

of variation (CV) close to 0%. This definitively confirms the accuracy of AD-BOX.

Furthermore, comparison studies putting AD-BOX against general-purpose load rating software for all 15 standard and four custom

vehicle types (results are provided by Ohio DOT) consistently showed a mean RF ratio

of approximately 1.0, with a CV up to 3.72%. These results strongly affirm the reliability

of our proposed methodology.

|