Failure, Fracture and Fatigue laboratory Facilities

EXPERIMENTAL FACILITIES

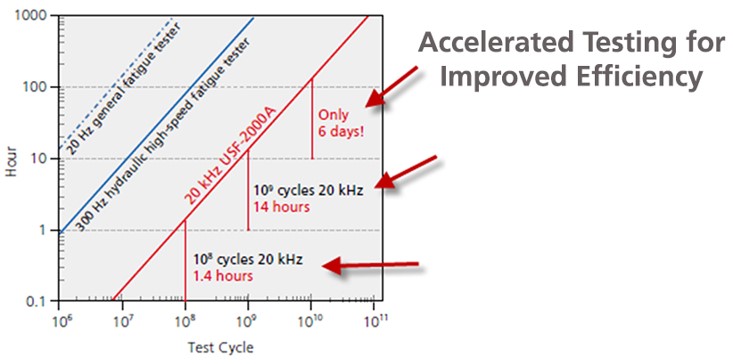

Ultrasonic Fatigue testing (USF-2000A)

•Very High (Giga) Cycle Fatigue

•Very High (Giga) Cycle Fatigue

ARBM 120 AMSLER ROTARY BENDING

- Equipped with an AHTF 850-A high-temperature furnace

- Cycle counts to 109 can be configured

- The rotating bar bending fatigue test can be performed at elevated temperatures up to 850°C.

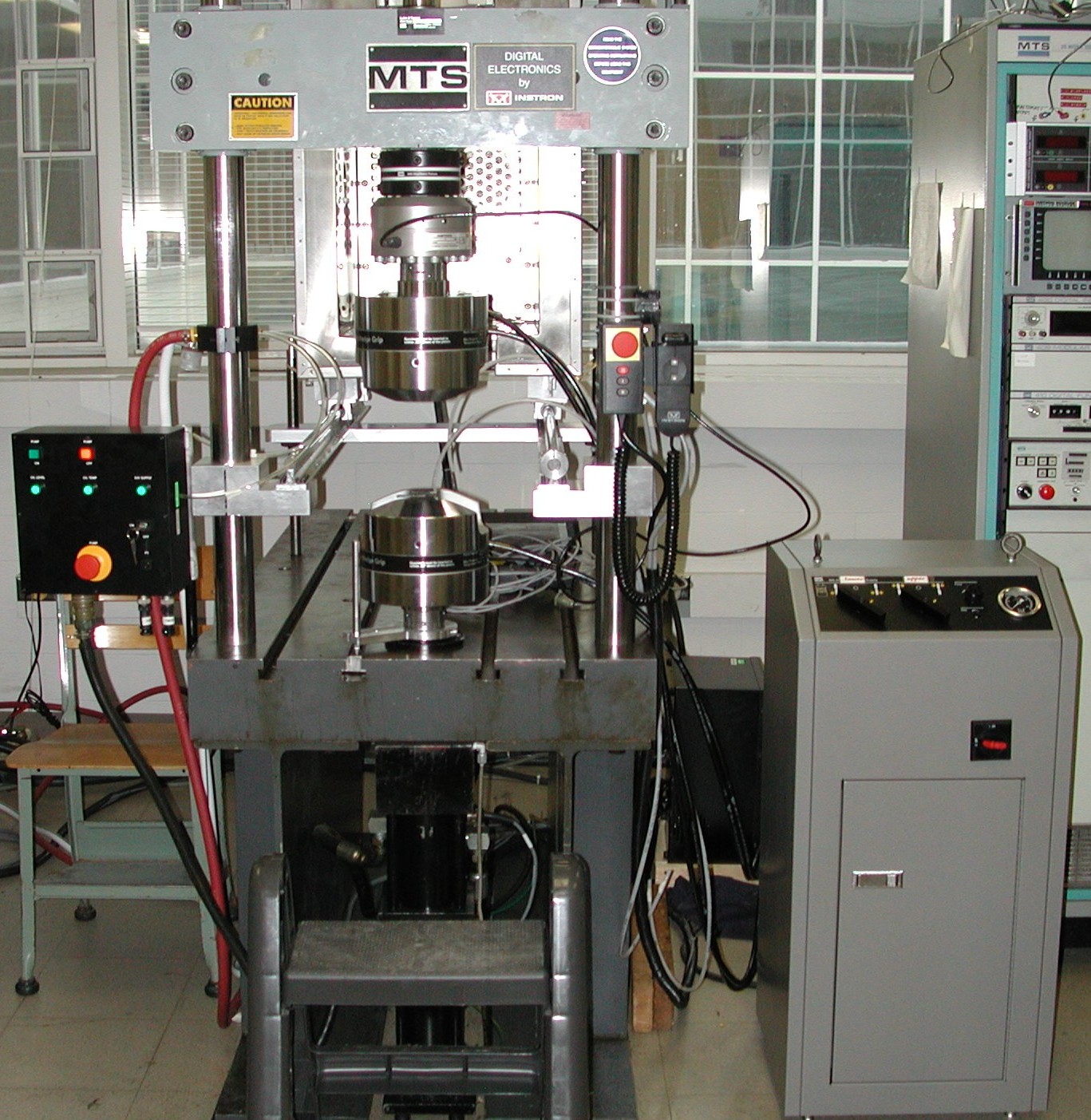

hydraulic 100kN axial load frame

MTS Closed-loop servo-controlled hydraulic 100kN axial load frame with Instron Digital

Servo-controller with an environmental chamber

MTS Closed-loop servo-controlled hydraulic 100kN axial load frame with Instron Digital

Servo-controller with an environmental chamber

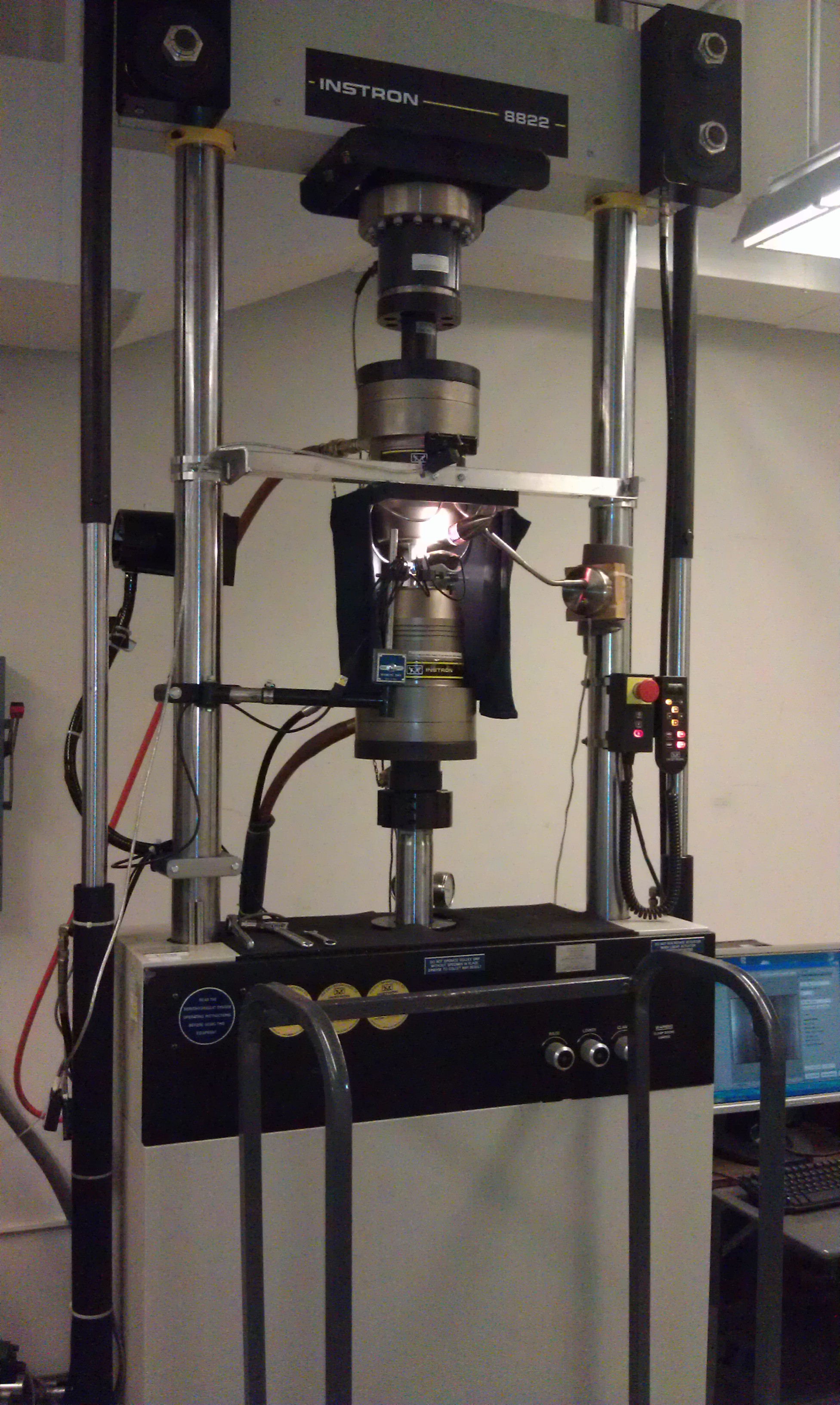

biaxial (axial and torsion) load frame

Instron closed-loop servo-controlled biaxial (axial and torsion) load frame with a

100kN axial and 1kNm torsion capacity

Instron closed-loop servo-controlled biaxial (axial and torsion) load frame with a

100kN axial and 1kNm torsion capacity

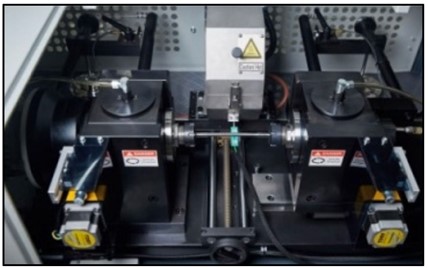

MEG 20TT

The MEG 20TT is a high temperature ultrasonic fatigue tester. Capacity is 20 kN and

max temperature is 1200 degrees C

The MEG 20TT is a high temperature ultrasonic fatigue tester. Capacity is 20 kN and

max temperature is 1200 degrees C

TYPICAL TESTING

-

Tensile testing

-

Strain-controlled fatigue testing (e-N)

-

Load-controlled fatigue testing (S-N)

-

Fatigue crack growth testing (da/dN-DK)

-

Fracture toughness testing (K1c, J1c, R-curve)

-

Component fatigue testing

-

Spectrum cyclic loading

-

Creep testing

-

Hot and cold temperature testing

-

Fractomat Crack Detecting System

-

Scanning Electron Microscope (SEM)

-

Software capabilities