Failure, Fracture and Fatigue Laboratory (F3L)

What is failure, fracture and fatigue?

Damage leads to failure and failure leads to fracture. Fracture is a form of failure where the material separates in pieces due to stress, at temperatures below the melting point. Fatigue causes an estimated 90% of all mechanical service failures. Fatigue failures occur under fluctuating stresses that are much lower than the stress required to cause failure during a single application. Fatigue can affect any part or component that moves. Automobiles on roads; aircraft wings and fuselages in the air; ships at sea; nuclear reactors; jet engines; and land-based turbines are all subject to fatigue failures [ASTM International].

The Failure, Fracture, and Fatigue Laboratory (F3L) is a research laboratory in the Department of Mechanical, Industrial, and Manufacturing Engineering (MIME) at The University of Toledo with two major goals:

- To assess failure and fracture, including fatigue, of materials and structures in bulk- and microscale

- To educate engineering leaders in the field

Current research areas

- Uniaxial and multiaxial fatigue of metals and non-metals

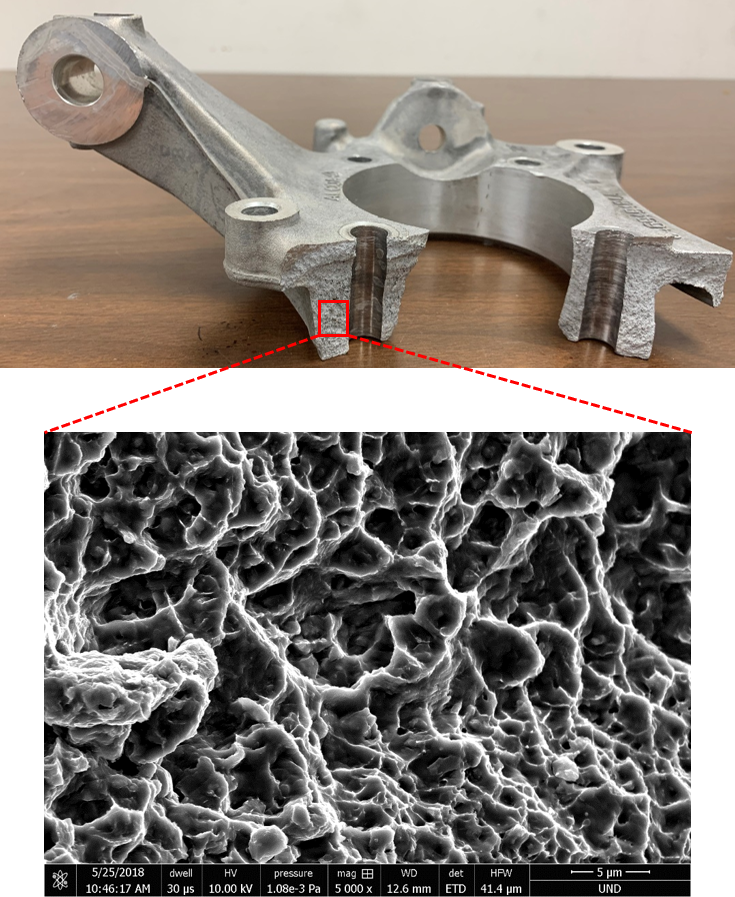

- Fatigue of additive manufactured metals (MAM)

- Fatigue in small scales (i.e. indentation fatigue)

- Ultrasonic fatigue to assess very high cycle fatigue (VHCF)

- Non-ambient rotating bending fatigue

Research areas

- Uniaxial and multiaxial fatigue of metals and non-metals

- Fatigue of additive manufactured metals (MAM)

- Fatigue in small scales (i.e. indentation fatigue)

Facilities

Publications

News

Sponsors

- UToledo URFO

- (AFOSR) Department of Defense

- Eaton Corporation

- National Institute of Standards and Technology (NIST)

- SLM Solution

- Lincoln Electric

- Quintus Technologies

History

Contact

North Engineering Room 1037

Email: Meysam.Haghshenas@utoledo.edu

Office phone: 419-530-8241