Fall 2018 Design Projects

Project List

- Swarm Robot Boat

- Enrichment Launching Mechanism "Cheetapult"

- UT Greywater System for Parks Tower

- Adaptive Tricycle

- Modification and User Testing of a Hand Operated Tricycle

- Nitinol Actuated Prosthetic Hand

- T-Shirt Gatling Gun

- Rocket RC Blimp for UT Athletics

- FCA Dundee Engine Plant Process Improvement

- Snow Adhesion Testing

- Low-cost 3D Printer Benchmarking and Upgrade

- Processing and Characterization of Medical Cements

- Toledo Transducer Manufacturing Anomaly Analysis

- High-Precision Adjustable Secondary Mirror Mechanism

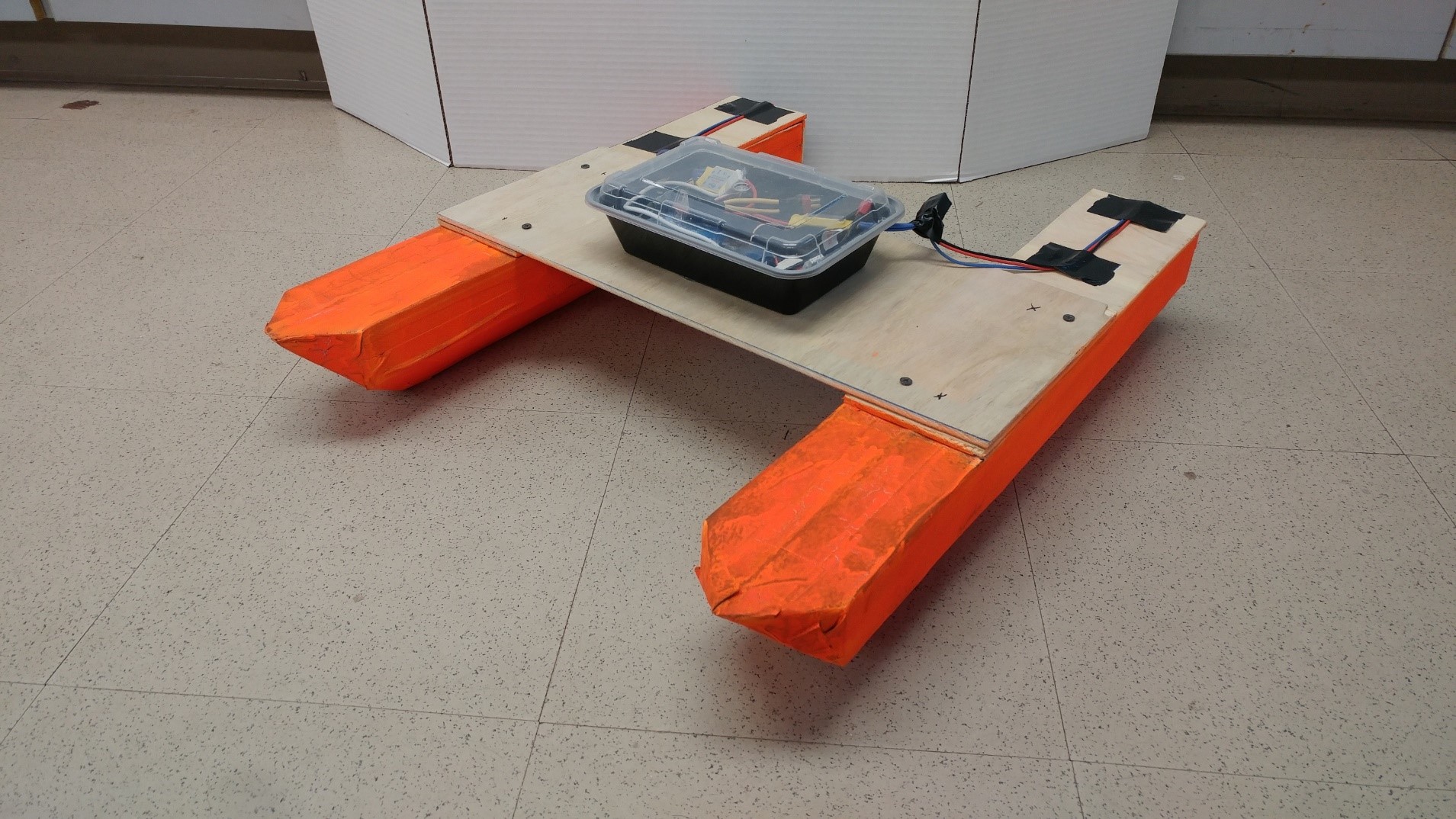

This project entails designing and manufacturing swarm robot boats. Using GPS and

an onboard computer, the robots could communicate and work together on a variety of

different tasks. The swarm boats have previously been used to collect algae from the

surface of a pond, by dragging around nets behind the boats. Utilizing onboard GPS,

the robots have the potential to avoid collisions and efficiently cover a large area

of water.

This project entails designing and manufacturing swarm robot boats. Using GPS and

an onboard computer, the robots could communicate and work together on a variety of

different tasks. The swarm boats have previously been used to collect algae from the

surface of a pond, by dragging around nets behind the boats. Utilizing onboard GPS,

the robots have the potential to avoid collisions and efficiently cover a large area

of water.

There are even more applications this boat could be adapted for, thanks to the flexibility of the onboard computer. Another potential application would be water quality analysis. By adding other sensors such as thermometers, the swarm boat could serve as a useful research data collection tool.

This project was brought to the senior design course through the University of Toledo’s Mechanism, Mobility, Multifunctional Design Laboratory (3MDL for short), which is a lab dedicated to the research of advanced mechanism design lead by Dr. Brain Trease. This swarm robot project is not a new one: two previous senior design groups and a few members of the 3MDL staff have taken the design through its first five generations, and we were tasked with designing the sixth generation this semester.

Team Members: Michael Docis – Group Leader; Jonathan Hendrzak – Technical Liaison; Alex Creeger

– Purchasing Agent; Feijie Chen – Communications Specialist

Team Members: Michael Docis – Group Leader; Jonathan Hendrzak – Technical Liaison; Alex Creeger

– Purchasing Agent; Feijie Chen – Communications Specialist

Faculty Advisor: Dr. Brian Trease; Client Advisor: Dr. Adam Schroeder; Project Sponsor: University of Toledo’s Mechanism, Mobility, Multifunctional Design Laboratory (3MDL)

Special Thanks: Dr. Adam Schroeder, for his enthusiastic support and for his tremendous assistance with the program; Dr. Brian Trease, for his continued support and bountiful ideas; 3MDL personnel, especially Terry Schulin and Lauren Marshall

Our project was to create some sort of launcher for the Toledo Zoo for them to launch

enrichment items such as food and toys into the enclosures to try and get the animals

more active. Originally, we thought it was just for the cheetah’s but once we got

to the zoo we found out it was for multiple animals such as the wolves, gorillas,

and all the animals in the safari enclosure. Our client gave us some requirements

that it needed to meet. It needed to be mobile, light and adjustable so that the zoo

employees can move it easily to the different enclosures. We were told that it can’t

be compressed air as it could scare the animals. Our project had an initial design

which involved springs which didn’t work out because it didn’t launch items far enough

and it was way too heavy for what the zoo wanted. The second design was a slingshot

design that was made of wood and had wheels on it to make it transportable. This ended

up working very well and met all the requirements.

Our project was to create some sort of launcher for the Toledo Zoo for them to launch

enrichment items such as food and toys into the enclosures to try and get the animals

more active. Originally, we thought it was just for the cheetah’s but once we got

to the zoo we found out it was for multiple animals such as the wolves, gorillas,

and all the animals in the safari enclosure. Our client gave us some requirements

that it needed to meet. It needed to be mobile, light and adjustable so that the zoo

employees can move it easily to the different enclosures. We were told that it can’t

be compressed air as it could scare the animals. Our project had an initial design

which involved springs which didn’t work out because it didn’t launch items far enough

and it was way too heavy for what the zoo wanted. The second design was a slingshot

design that was made of wood and had wheels on it to make it transportable. This ended

up working very well and met all the requirements.

Team Members: Group Leader – Derich Weiland; Technical Liaison – Joseph Leitch; Purchasing Agent – Carl Herron; Webpage Specialist – Toby Lawton

Faculty Advisor: Dr. Sorin Cioc; Client Advisor: Beth Posta; Project Sponsor: Toledo Zoo

Special Thanks: Beth Posta, Toledo Zoo – For access to the zoo and being our contact; Bill Weiland, Derich’s father – Access to farm with tools, material, and initial testing place; Dr. Cioc, University of Toledo – Main source of guidance

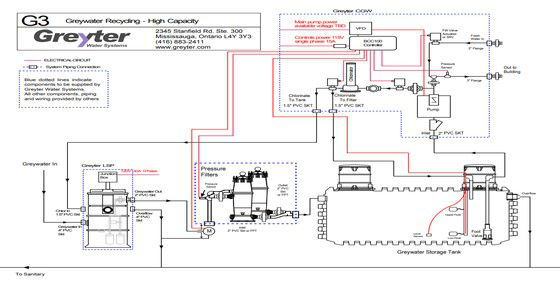

Our group was tasked with determining if a greywater filtration system is viable for

Parks Tower. A greywater filtration system could help the university become more environmentally

friendly as well possibly provide a large cost savings. After research, we determined

it will be possible to collect and filter all shower water and pump the filtered water

back into Parks Tower to supply the toilets. Our group found 4 other systems that

could use any excess filtered water, these are: redirecting water to the river, using

it in cooling towers on campus, using it in the boiler system, or divert it to city

sewage. A cost analysis was performed for all 4 methods and ROI was calculated, with

the best being 40 years. The group concluded a greywater system would best be installed

in any new structure to be built on campus, not a standing structure like Parks Tower.

This project will be passed on to next semester where they may determine if there

is a viable way to implement any of these designs or come up with new designs.

Our group was tasked with determining if a greywater filtration system is viable for

Parks Tower. A greywater filtration system could help the university become more environmentally

friendly as well possibly provide a large cost savings. After research, we determined

it will be possible to collect and filter all shower water and pump the filtered water

back into Parks Tower to supply the toilets. Our group found 4 other systems that

could use any excess filtered water, these are: redirecting water to the river, using

it in cooling towers on campus, using it in the boiler system, or divert it to city

sewage. A cost analysis was performed for all 4 methods and ROI was calculated, with

the best being 40 years. The group concluded a greywater system would best be installed

in any new structure to be built on campus, not a standing structure like Parks Tower.

This project will be passed on to next semester where they may determine if there

is a viable way to implement any of these designs or come up with new designs.

Team Members: Brandon Wolters – Group Leader; Gabe Walters – Technical Liaison; Jonathan Estes

– Purchasing Agent; John Hayes – Web Developer; Keenan Coon – Industrial Engineering

Specialist

Team Members: Brandon Wolters – Group Leader; Gabe Walters – Technical Liaison; Jonathan Estes

– Purchasing Agent; John Hayes – Web Developer; Keenan Coon – Industrial Engineering

Specialist

Faculty Advisor: Dr. Brian Trease; Client Advisor: Michael Green; Project Sponsor: University of Toledo

Special Thanks: Ryan Gierhart from the Ohio EPA (Northwest Region); Lucas County Health Dept.; Greyter Water Systems; Wahaso (Water Harvesting Solutions) The Toledo Ability Center aims to give the disabled a path to independence. In this

project, their client Willy has autism and cannot currently ride a bike or tricycle

with his family as the result of having balancing deficiencies. Thus, this project

aims to design a stylish and customized tricycle that will keep Willy aesthetic. The

designed tricycle will need to have non-restrictive restraints while still firmly

securing the client. In addition, the tricycle needs to be adjustable to account for

Willy’s growth. The main goal, however, will be to maintain a safe functional tricycle

for Willy, and thus, it will need to sustain a high factor of safety.

The Toledo Ability Center aims to give the disabled a path to independence. In this

project, their client Willy has autism and cannot currently ride a bike or tricycle

with his family as the result of having balancing deficiencies. Thus, this project

aims to design a stylish and customized tricycle that will keep Willy aesthetic. The

designed tricycle will need to have non-restrictive restraints while still firmly

securing the client. In addition, the tricycle needs to be adjustable to account for

Willy’s growth. The main goal, however, will be to maintain a safe functional tricycle

for Willy, and thus, it will need to sustain a high factor of safety.

Teams Members: Tyler Drees, Jay Nagy, Jeremy Keil, Collin McCabe, Mohammed Alotaibi;

Teams Members: Tyler Drees, Jay Nagy, Jeremy Keil, Collin McCabe, Mohammed Alotaibi;

Faculty Advisor: Dr. Mohamed Samir Hefzy; Client Advisor: Angie Goodnight; Project Sponsor: The Toledo Ability Center

Special Thanks: Wersell’s Bike Shop & Rifton Our client Dolores Guinn is an Army veteran who has lost motor function in her legs

due to illness. She is an avid outdoorsman and hunter who wants to continue to do

what she loves despite not being able to walk. As a result, she has asked for a hand-powered

tricycle that she can use to hunt and ride on in the woods behind her house. To meet

her needs, we met with her throughout the semester to grasp a better idea of what

functions Dolores really needed first, which ranged from multiple gears to forward

and reverse function of the bike.

Our client Dolores Guinn is an Army veteran who has lost motor function in her legs

due to illness. She is an avid outdoorsman and hunter who wants to continue to do

what she loves despite not being able to walk. As a result, she has asked for a hand-powered

tricycle that she can use to hunt and ride on in the woods behind her house. To meet

her needs, we met with her throughout the semester to grasp a better idea of what

functions Dolores really needed first, which ranged from multiple gears to forward

and reverse function of the bike.

By the end of the semester, we produced a working tricycle that moves in forward and reverses through all 3 gears and was built from standard bicycle parts, in order to maintain the simplicity of design and repair. The final test drive included Dolores herself pulling our group leader Bryon on a sled to simulate dragging an animal. The final result was that the tricycle functioned as intended with and without weight added.

Team Members: Bryon Jordan- Group Leader; Jeffrey Banachowski- Purchasing Agent; Thomas Garner-

Technical Liaison; Dustin Reeder- Communications Contact

Team Members: Bryon Jordan- Group Leader; Jeffrey Banachowski- Purchasing Agent; Thomas Garner-

Technical Liaison; Dustin Reeder- Communications Contact

Faculty Advisor: Dr. Adam Schroeder; Client Advisor: Dolores Guinn; Project Sponsor: Angie Goodnight, Toledo Ability Center

Special Thanks: Garner Precision Collision, Toledo Bikes

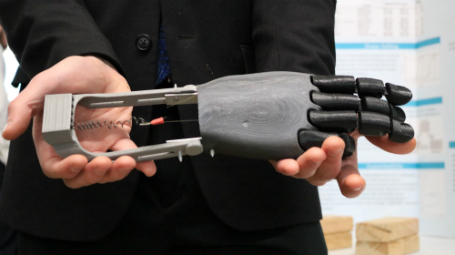

Nitinol is a shape memory alloy made from nickel and titanium. Shape memory alloys

express the ability to “remember” a set shape. When deformed, heat can be applied

to eliminate residual strain left on the material, causing it to return to its “memorized

shape”. This unique property provides the opportunity to convert heat energy into

mechanical energy. Our group applied this concept to a 3D printed prosthetic hand.

Sending electricity through nitinol springs heats up the nitinol and forces it to

contract. The springs pull wires that run through the hand and fingers. This allows

us to manipulate and bend the fingers for effortless movement.

Nitinol is a shape memory alloy made from nickel and titanium. Shape memory alloys

express the ability to “remember” a set shape. When deformed, heat can be applied

to eliminate residual strain left on the material, causing it to return to its “memorized

shape”. This unique property provides the opportunity to convert heat energy into

mechanical energy. Our group applied this concept to a 3D printed prosthetic hand.

Sending electricity through nitinol springs heats up the nitinol and forces it to

contract. The springs pull wires that run through the hand and fingers. This allows

us to manipulate and bend the fingers for effortless movement.

Team Members: Bryce Williams, Marcus Ardner, Nate Durkovic

Team Members: Bryce Williams, Marcus Ardner, Nate Durkovic

Faculty Advisor: Dr. Elahinia; Client Advisor: Mohammadreza Nematollahi; Project Sponsor: Dr. Elahinia

Special Thanks: Maker Society

The University of Toledo Athletic Department has a tradition of providing an engaging

and exciting experience for its sports fans. At the beginning of our semester, the

department approached us about designing a device that would further increase the

level of excitement for fans.

The University of Toledo Athletic Department has a tradition of providing an engaging

and exciting experience for its sports fans. At the beginning of our semester, the

department approached us about designing a device that would further increase the

level of excitement for fans.

Currently, the University uses two carbon dioxide powered t-shirt cannons to launch shirts during timeouts and stoppages of play. These cannons work but are relatively unreliable and the Athletic Department thought that we could design something more reliable that would also make the experience more exciting. After discussing the idea with our team, we decided that a Gatling style cannon that sequentially launched shirts out of multiple barrels would be the answer.

After 4 months of work, we are proud to present the Athletic department with our solution, and hope they will be able to use it to help create an even better environment for the University’s sports fans.

Team Members: Ryan O’Callaghan, Richard Gobrecht, Evan Hartenburg, Tyler Sullivan

Team Members: Ryan O’Callaghan, Richard Gobrecht, Evan Hartenburg, Tyler Sullivan

Faculty Advisor: Dr. Sorin Cioc; Client Advisor: Adam Simpson; Project Sponsor: UT Athletic Department

Special Thanks: John Jaegly, Tim Grivanos, and the Entire M.I.M.E. Machine Shop Our group was tasked with creating a UT Athletics equivalent of the Toledo Walleye

‘Super Spike’ RC drone powered blimp. UT Athletics is currently looking at options

to increase crowd engagement during stoppages of play. A remote-controlled blimp,

similar to ‘Super Spike’, could be used to drop prizes on the fans at Toledo sports

games. By designing the drone portion of this project, we have been able to complete

a custom built which includes the blimp controlling capabilities as well as a prize

drop mechanism. Because of its modularity, it will be possible to add additional features

as desired in the future.

Our group was tasked with creating a UT Athletics equivalent of the Toledo Walleye

‘Super Spike’ RC drone powered blimp. UT Athletics is currently looking at options

to increase crowd engagement during stoppages of play. A remote-controlled blimp,

similar to ‘Super Spike’, could be used to drop prizes on the fans at Toledo sports

games. By designing the drone portion of this project, we have been able to complete

a custom built which includes the blimp controlling capabilities as well as a prize

drop mechanism. Because of its modularity, it will be possible to add additional features

as desired in the future.

Team Members: Scott Brittenham, Richard Gahutu, Michael Kranz, and Thomas Walbom

Team Members: Scott Brittenham, Richard Gahutu, Michael Kranz, and Thomas Walbom

Faculty Advisor: Dr. Robert Langenderfer

Client Advisor: Mr. Adam Simpson

Project Sponsor: University of Toledo Athletics Department

Special Thanks: The Toledo Walleye and Huntington Center

The objective of this senior design project is to identify and improve upon processes

that are hindering the speed and reliability of the World Gas Engine and Tigershark

4-cylinder engine line at the Fiat-Chrysler Engine Plant in Dundee, Michigan. Our

client and his co-workers have decided there is a bottleneck in the system, but have

yet to come to a conclusion as to what the main issue is. They have brought our team

in to have a fresh set of eyes on the issues and provide on the ground support. FCA

wanted us to proceed with Option 2: Finding a motor, gearbox and other components

that would be able to increase the speed of the conveyor system. After extensive research

and contacting the suppliers, we found a system that would improve the speed by 6

m/min without hindering the performance of the line. After conducting multiple time trials, we

decided that we needed to implement a faster motor and gearbox combination than what

was suggested to get us up to 18m/min. Upgrading to this system will improve overall

travel time by 15 seconds. This will also require additional add-ons of heavy duty

stop gates. This is so the stop gates can handle the load of an entire queue full

of pallets. This would save approximately $3.2 million per year considering the production

line runs 40 hours per week.

The objective of this senior design project is to identify and improve upon processes

that are hindering the speed and reliability of the World Gas Engine and Tigershark

4-cylinder engine line at the Fiat-Chrysler Engine Plant in Dundee, Michigan. Our

client and his co-workers have decided there is a bottleneck in the system, but have

yet to come to a conclusion as to what the main issue is. They have brought our team

in to have a fresh set of eyes on the issues and provide on the ground support. FCA

wanted us to proceed with Option 2: Finding a motor, gearbox and other components

that would be able to increase the speed of the conveyor system. After extensive research

and contacting the suppliers, we found a system that would improve the speed by 6

m/min without hindering the performance of the line. After conducting multiple time trials, we

decided that we needed to implement a faster motor and gearbox combination than what

was suggested to get us up to 18m/min. Upgrading to this system will improve overall

travel time by 15 seconds. This will also require additional add-ons of heavy duty

stop gates. This is so the stop gates can handle the load of an entire queue full

of pallets. This would save approximately $3.2 million per year considering the production

line runs 40 hours per week.

Team Members: Abdel Hakim Abou Yassine, Brendan Bennekamper, John Heninger, and Benjamin Nadarajah

Faculty Advisor: Dr. Franchetti; Client Advisor: John Montri; Project Sponsor: FCA Dundee Engine Plant

Special Thanks: Dr. Trease, Dr. Franchetti, and FCA Dundee Engine Plant. For this leg of a multi-part project, the design team's objective is to design an

experiment to test adhesion of snow to aluminum at differing Liquid Water Contents

and test each of the experiments to gather data points. A secondary goal is to design

a way to test snow adhesion on different materials. Moving forward the data gathered

from various testing can help us understand and quantify how snow adheres to different

materials with the ultimate goal of designing a way to passively remove snow from

cable stay bridges, smart car camera lenses, and the sides of ships sailing through

cold waters.

For this leg of a multi-part project, the design team's objective is to design an

experiment to test adhesion of snow to aluminum at differing Liquid Water Contents

and test each of the experiments to gather data points. A secondary goal is to design

a way to test snow adhesion on different materials. Moving forward the data gathered

from various testing can help us understand and quantify how snow adheres to different

materials with the ultimate goal of designing a way to passively remove snow from

cable stay bridges, smart car camera lenses, and the sides of ships sailing through

cold waters.

Team Members: Kyle Stallings, Jesse Haefka, Khaled Alresayes and Joel McVicker Jr.

Faculty Advisor: Dr. Hossein Sojoudi and Dr. Douglas Nims

Client Advisor: Dr. Hossein Sojoudi and Dr. Douglas Nims

Special Thanks: Dr. Sojoudi, Dr. Nims, Jamie Heil, Mehdi Sarayloo, Behrouz Mohammadian, Mr. Jaegly

The OneUp 3D printer was released in 2013 as the first 3D printer available for under

$200. Dr. Rizvi purchased this printer from Kickstarter but did not manage to get

it working. The printer was made of low-quality materials, such as MDF board and zip

ties, and also used a very outdated slicer. After a senior design group got the OneUp

to print at a low quality, this team was tasked with upgrading the printer in terms

of print quality, build volume, and material compatibility. A new board was installed

on the OneUp and after using a new slicer and updated firmware, the OneUp was printing

better than before. With Dr. Rizvi’s guidance, the decision was made to build a brand-new

printer with parts designed by this group. The new printer named “Theseus” was, an

upgrade in virtually every aspect when compared to the OneUp. The new frame, gantry,

additional z-screw, build plate, print head, hot end, and cooling system all increased

the printer’s quality. After testing the Theseus printer, the print quality was much

better than the OneUp and was even comparable with more expensive printers such as

Makerbots and Ultimakers.

The OneUp 3D printer was released in 2013 as the first 3D printer available for under

$200. Dr. Rizvi purchased this printer from Kickstarter but did not manage to get

it working. The printer was made of low-quality materials, such as MDF board and zip

ties, and also used a very outdated slicer. After a senior design group got the OneUp

to print at a low quality, this team was tasked with upgrading the printer in terms

of print quality, build volume, and material compatibility. A new board was installed

on the OneUp and after using a new slicer and updated firmware, the OneUp was printing

better than before. With Dr. Rizvi’s guidance, the decision was made to build a brand-new

printer with parts designed by this group. The new printer named “Theseus” was, an

upgrade in virtually every aspect when compared to the OneUp. The new frame, gantry,

additional z-screw, build plate, print head, hot end, and cooling system all increased

the printer’s quality. After testing the Theseus printer, the print quality was much

better than the OneUp and was even comparable with more expensive printers such as

Makerbots and Ultimakers.

Team Members: Luke Poston Team Leader; Patrick Shemenski, Technical Liaison; Anthony Coustillac, Purchasing Agent; Dejan Orsag Web Page Specialist

Faculty Advisor and Client Advisor: Dr. Reza Rizvi

Special Thanks to the UT Makers Society

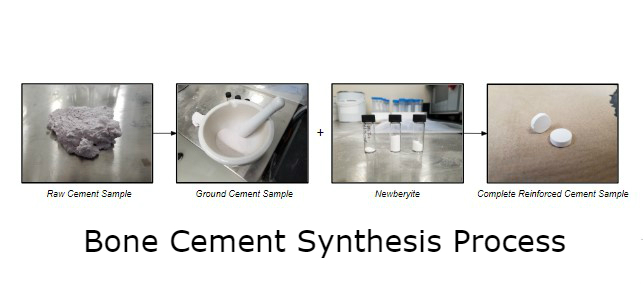

Bone cement is used in many different surgical situations ranging from dental surgery

to spinal surgery. The current types of bone cement behave like ceramic with low

elastic strength. Because of the low elastic strength, developers desire as high

of compression and tensile strength as possible. The objective of this project is

to improve the compressive strength and the injectability of our client, Dr. Bhaduri’s,

FDA approved Orthopaedic Medical Cement. This bone cement is used in bone fractures

to minimize the hospital time, speed up recovery, and causes less pain to the patient

when applied correctly. The bone cement is completely biodegradable and biocompatible,

which is an important parameter that the project team had to consider when formulating

potential design solutions to increase the injectability and compressive strength.

This bone cement an also be utilized for dental applications and small bone fractures,

thus making it a viable solution for many orthopedic applications performed every

day. The compressive strength of the material needs to be improved, along with the

injectability properties. Throughout this report, the project team developed potential

solutions to each of these main objectives, and then testing procedures were also

determined. A final conclusion and a path forward was developed at the end of the

report.

Bone cement is used in many different surgical situations ranging from dental surgery

to spinal surgery. The current types of bone cement behave like ceramic with low

elastic strength. Because of the low elastic strength, developers desire as high

of compression and tensile strength as possible. The objective of this project is

to improve the compressive strength and the injectability of our client, Dr. Bhaduri’s,

FDA approved Orthopaedic Medical Cement. This bone cement is used in bone fractures

to minimize the hospital time, speed up recovery, and causes less pain to the patient

when applied correctly. The bone cement is completely biodegradable and biocompatible,

which is an important parameter that the project team had to consider when formulating

potential design solutions to increase the injectability and compressive strength.

This bone cement an also be utilized for dental applications and small bone fractures,

thus making it a viable solution for many orthopedic applications performed every

day. The compressive strength of the material needs to be improved, along with the

injectability properties. Throughout this report, the project team developed potential

solutions to each of these main objectives, and then testing procedures were also

determined. A final conclusion and a path forward was developed at the end of the

report.

Team Members: Jacob Ritchart, Ryan Kahle, Seth Bell, Brent Biernacki

Team Members: Jacob Ritchart, Ryan Kahle, Seth Bell, Brent Biernacki

Faculty Advisor and Client Advisor: Dr. Sarit Bhaduri

Project Sponsor: National Science Foundation

Special Thanks: Terry Schulin

Load cell manufacturer Toledo Transducer is experiencing a high reject rate of 30%

for one specific model of transducers due to sensor linearity errors. Manufacturing

of the load cell after machining is believed to be the root of these failures, specifically

grit blasting. Our group’s project was to find the root cause of the linearity errors

and then try to propose a solution to it. All the while documenting our findings.

Sample parts were obtained and measured in a blind test using the university’s coordinate

measuring machine as well as pressure indicating film. We achieved a solution after

doing various measurement and calibration tests to sample parts pre- and post- grit

blasting and came to a definitive solution to the problem.

Load cell manufacturer Toledo Transducer is experiencing a high reject rate of 30%

for one specific model of transducers due to sensor linearity errors. Manufacturing

of the load cell after machining is believed to be the root of these failures, specifically

grit blasting. Our group’s project was to find the root cause of the linearity errors

and then try to propose a solution to it. All the while documenting our findings.

Sample parts were obtained and measured in a blind test using the university’s coordinate

measuring machine as well as pressure indicating film. We achieved a solution after

doing various measurement and calibration tests to sample parts pre- and post- grit

blasting and came to a definitive solution to the problem.

Team Members: Kyle Breymaier - Communications Specialist; Scot Lamparter - Assistant to the Technical Liaison; Timothy Reed - Group Leader; Chip Rowe - Purchasing Agent; Austin Warchol - Technical Liaison

Faculty Advisor: Dr. John Jaegly; Client Advisor: Brad Mettert; Project Sponsor: Toledo Transducer

Special Thanks: Special thanks to John Jaegly, and Brad Mettert for all the help they gave

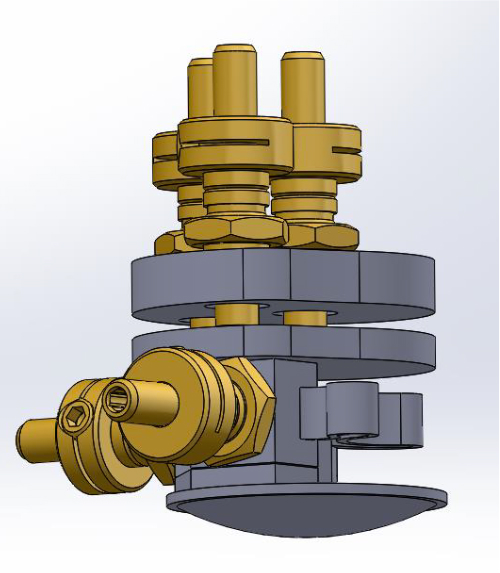

The goal for our project is to design a high precision mirror mount to help align

a secondary mirror on optical communications satellites for NASA Glenn Research Center.

The mechanism will need to have five degrees of freedom and use precision calibration

for permanent alignment of the mirror. The cross-sectional area of the mechanism must

as small as possible so that there is minimal blockage of the signal. NASA is researching

the use of optical communications because it allows data to be transferred up to 10

times faster than with radio waves. Optical communication is projected to be the future

of data transmission in space applications.

The goal for our project is to design a high precision mirror mount to help align

a secondary mirror on optical communications satellites for NASA Glenn Research Center.

The mechanism will need to have five degrees of freedom and use precision calibration

for permanent alignment of the mirror. The cross-sectional area of the mechanism must

as small as possible so that there is minimal blockage of the signal. NASA is researching

the use of optical communications because it allows data to be transferred up to 10

times faster than with radio waves. Optical communication is projected to be the future

of data transmission in space applications.

Team Members: Tyler Smith, Ciaran Duffy, Nick Pasquale, Michael McQuillen

Team Members: Tyler Smith, Ciaran Duffy, Nick Pasquale, Michael McQuillen

Faculty Advisor: Dr. Brian Trease

Client Advisor: Kelly McEntire

Project Sponsor: NASA Glenn Research Center