Spring 2018 Design Projects

Projects

- Alternative Method to Press a Sewing Machine Foot Pedal

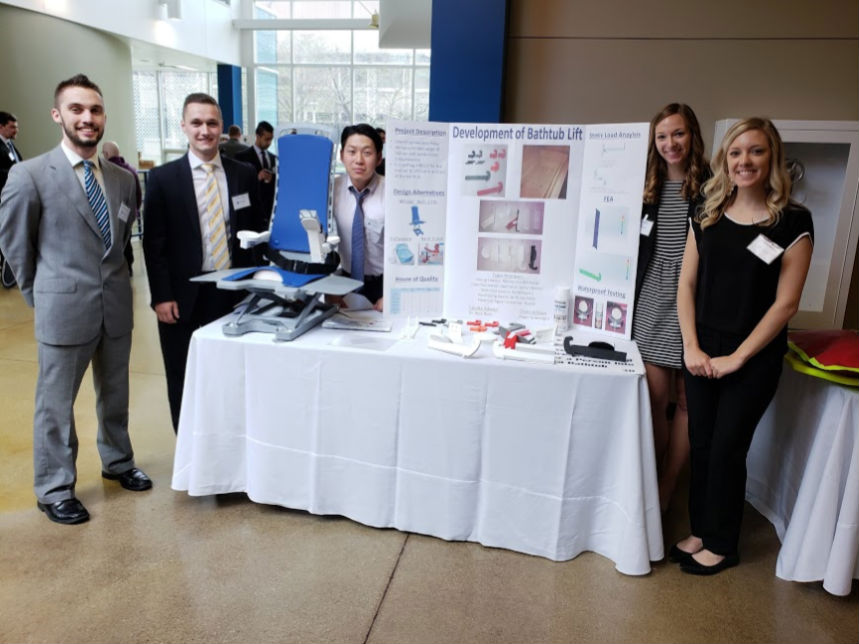

- Development of a Bathtub lift

- Device to Assist in using a toilet

- Beach Wheelchair

- Restoration of a Pratt & Whitney R-4360 Aircraft Engine

- Analysis and Improvement of a Motorcycle Rear Suspension

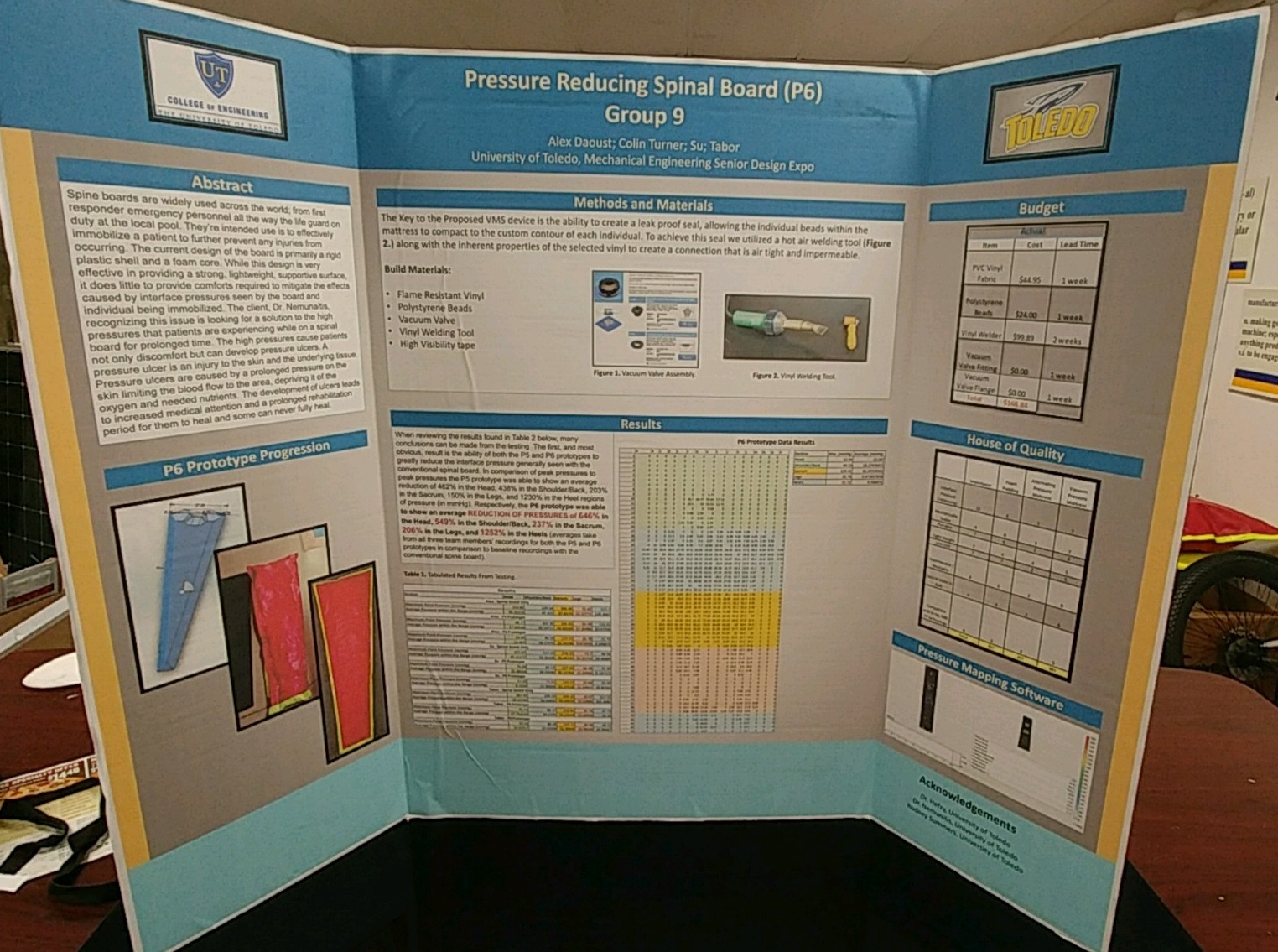

- Pressure reducing spinal board

- Portable Wheelchair Scale

- Portable Wheelchair Ramp

- Multi-person Human Powered Vehicle

- Aerostat for Monitoring Harmful Algae Blooms

- NASA Mining Robot

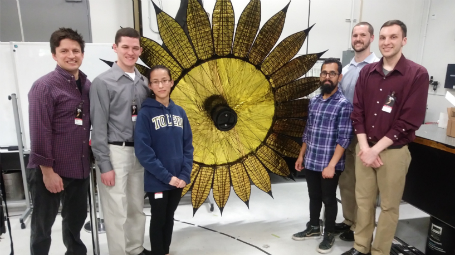

- NASA Deployable Wrap-Rib Space Structure

- Hydro Power Modeling

- 360kW Photovoltaic Array for Health Science Campus

- Leaf Filter De-Icer

- Plastic Densification

- Maker Space Redesign

- Toledo Zoo Wolf Exhibit Puzzle Platform

- Data Acquisition System for the University of Toledo's Formula SAE team

This project aims to adapt the Singer sewing machine of a woman with a spinal cord injury to enable her to use it without the foot pedal

Design Team Members: Melissa Ballasch, Brandon Kistler, Sarah Wojnarowski, Katie Hoenie

Faculty Advisor: Dr. Hongyan Zhang Client Advisor: the Ability Center of Greater Toledo

Project Sponsor: Wacker

Special Thanks to Dr. Zhang, John Jaegly, Tim Grivanos, Terry Kahle

The purpose of this project is to give an individual with a severe form of Cerebral Palsy independence. Cerebral Palsy is a condition that affects body movement and muscle coordination. A very small and limited range of motion gives him minimal ability to perform any day-to-day tasks. Because he can’t do many of these everyday activities, his caregiver is responsible for helping him. As both the client and the caregiver grow older, it is becoming more and more strenuous on them both, especially for the caregiver. This project was designed to help the client safely gain independence during relaxation in the bathtub, while also giving the caregiver a break. Currently, his mother lowers him into the tub, holds him in a secure position while washing him in the bathtub, then lifts him out of the tub. A waterproof device with lowering/lifting capabilities and that gives peace of mind knowing he is secure in the bathtub is greatly desired for this specific situation. The device is required to lift 80 pounds, waterproof to prevent electrocution, hygienic to prevent mold growth, safe, and comfortable.

Design Team: Mackenzie Michalski, Jaclyn Melvin, Seokhwan Ji, Anthony Beier, Jonathan Krabill

Faculty Advisor: Dr. Reza Rizvi; Client Advisor: Angie Goodnight and the Ability Center of Greater Toledo; Project Sponsor: Wacker

Special Thanks to Dr. Reza Rizvi, University of Toledo, Dr. Lesley Berhan, University of Toledo, College of Engineering Machine shop: John Jaegly, University of Toledo Maker Space

The objective of this project is to design, analyze, construct, and test a device

to assist with the client, who has unfortunately  been affected by cerebral palsy, in using the toilet by himself without the assistance

of another human being. The main idea is that he would like some privacy when it comes

down to using the bathroom by himself. The device must be sturdy enough to support

at least 85 pounds, have a backrest with cushions, a seatbelt around the waist, footrest,

handrails to support the client, wheels and brakes, and have the ability to be out

of the way for other family members when they need to use the restroom also. This

device will help assist in using the restroom safely and properly while giving the

client the privacy that he deserves.

been affected by cerebral palsy, in using the toilet by himself without the assistance

of another human being. The main idea is that he would like some privacy when it comes

down to using the bathroom by himself. The device must be sturdy enough to support

at least 85 pounds, have a backrest with cushions, a seatbelt around the waist, footrest,

handrails to support the client, wheels and brakes, and have the ability to be out

of the way for other family members when they need to use the restroom also. This

device will help assist in using the restroom safely and properly while giving the

client the privacy that he deserves.

Design Team: Nicolette Hersch, Hadi Mohammed, Graham Goupille, Olivia Anders

Faculty Advisor: Dr. Reza Rizvi, Client Advisor: Angie Goodnight and the Ability Center of Greater Toledo

Project Sponsor: Wacker, Rand Industrial, The Ability Center of Greater Toledo

Special Thanks: We would like to give a special thanks to Dr. Reza Rizvi for being our faculty advisor and helping us throughout the semester with our project. We would also like to thank Rand Industrial Insulation for the kind donation towards our budget and supplying materials and labor to help complete the project.

The Ability Center of Greater Toledo was in need of a new wheelchair for beach use.

This chair will be available for use by anyone in need of using it. We designed the

chair for stability, safety, and ease of use while keeping it transportable. We were

able to improve on our design thanks to extra support and donations. We were all happy

to be a part of a little something that has the potential to give a higher quality

of life to its users.

The Ability Center of Greater Toledo was in need of a new wheelchair for beach use.

This chair will be available for use by anyone in need of using it. We designed the

chair for stability, safety, and ease of use while keeping it transportable. We were

able to improve on our design thanks to extra support and donations. We were all happy

to be a part of a little something that has the potential to give a higher quality

of life to its users.

Design Team: Patrick Delaney, William Lopez, Tammy Reynolds, Aaron Slabic

Faculty Advisor: Dr. Hongyan Zhang, Client Advisor: Angie Goodnight and the Ability Center of Greater Toledo

Project Sponsor: Wacker, The Ability Center of Greater Toledo

Special Thanks: The team so greatly appreciates the generosity of Barb and Yolanda Cousino, Joel Groover, and Susan Knox along with the anonymous donations given to help make this project come to life.

Design Team: Scott Sampson, Mitchell Minnch, Quinn Welly, Surabhi Bhagavatula

Faculty/Client Advisor: Dr. Ray Hixon; Project Sponsor: The University of Toledo, MIME Department

The client and advisor, Dr. Hixon, is an avid motorcyclist and super single class

racer and purchased this motorcycle approximately a year ago. When the bike was purchased

it was in a heavily modified state. Compared to the stock rear dual shock swing arm,

the rear suspension of this Yamaha SRX 600 has been swapped out, and the frame has

been adapted to a Yamaha SRX 400 swingarm, which mounts to a Rising Rate Linkage,

and a custom-made single motocross monotube spring-damper unit.

The client and advisor, Dr. Hixon, is an avid motorcyclist and super single class

racer and purchased this motorcycle approximately a year ago. When the bike was purchased

it was in a heavily modified state. Compared to the stock rear dual shock swing arm,

the rear suspension of this Yamaha SRX 600 has been swapped out, and the frame has

been adapted to a Yamaha SRX 400 swingarm, which mounts to a Rising Rate Linkage,

and a custom-made single motocross monotube spring-damper unit.

After a test run of the Motorcycle, Dr. Hixon felt unsatisfied with the performance of the rear suspension. The initial interpretation from Dr. Hixton’s test run is that the monoshock was very low in damping force, and then the damping force would suddenly increase part way through the stroke. Dr. Hixon wishes to use this bike as both a street bike and for use on a racetrack but does not intend to use this bike competitively. The initial task of this project is to evaluate the root cause of the sudden rise in damping and to evaluate if there is a single cause, or if there is a collective cause somewhere between the spring-damper unit and the suspension linkage itself.

Design Team: Matthew Long, Jason Schwind, Jonah Taylor, Drew Toth

Faculty/Client Advisor: Dr. Ray Hixon Project Sponsor: Dr. Ray Hixon

Sp ine boards are widely used across the world; from first responder emergency personnel

all the way the life guard on duty at the local pool. They’re intended use is to effectively

immobilize a patient to further prevent any injuries from occurring. The current design

of the board is primarily a rigid HDPE shell with a foam core. While this design is

effective in providing a strong, lightweight, and supportive surface, it does little

to reduce interface pressures generated on the skin over boney contacts with the spine

board. The client, Dr. Nemunaitis, recognizing this issue is looking for a solution

to the high pressures when individuals are strapped to the spine board. The high pressures

cause patients not only discomfort but can develop pressure injury to the tissues

below. Pressure injury is caused by a prolonged pressure to the blood vessels limiting

the blood flow and causing tissue damage. The development of pressure injury leads

to increased cost, medical attention and a prolonged immobilization for proper treatment.

ine boards are widely used across the world; from first responder emergency personnel

all the way the life guard on duty at the local pool. They’re intended use is to effectively

immobilize a patient to further prevent any injuries from occurring. The current design

of the board is primarily a rigid HDPE shell with a foam core. While this design is

effective in providing a strong, lightweight, and supportive surface, it does little

to reduce interface pressures generated on the skin over boney contacts with the spine

board. The client, Dr. Nemunaitis, recognizing this issue is looking for a solution

to the high pressures when individuals are strapped to the spine board. The high pressures

cause patients not only discomfort but can develop pressure injury to the tissues

below. Pressure injury is caused by a prolonged pressure to the blood vessels limiting

the blood flow and causing tissue damage. The development of pressure injury leads

to increased cost, medical attention and a prolonged immobilization for proper treatment.

The proposed design that we felt best suited all of the needs encapsulated within this project came from the inspiration of a vacuum sealed mattress. This design utilizes technologies currently in use within the medical and emergency first responder fields alike and has shown a real promise in reducing interference pressures. Our design is comprised of vinyl sheeting fused together; the mattress is filled with individual polystyrene beads, and trough the implication of a one-way vacuum fitting it allows an individual to draw a vacuum and remove the remaining air from the mattress. The benefit of this design allows the mattress to be custom fit to each individual in question, maximizing the potential load distribution of each individual, theoretically resulting in lessening the peak pressure loads commonly seen in conventional spinal boards.

Design Team: Colin Turner, Alex Daoust, Caoannan Su, Tabor Mclaughlin

Faculty Advisor: Dr. Mohamed Samir Hefzy, Client Advisor: Dr. Greg Nemunaitis, Metro Health

Project Sponsor: The University of Toledo

Special Thanks: Rodney Summers, University of Toledo – Lab tech of the lab used for testing; Carmo, Supplier of injection molded plastic and PVC components

The objective of this project is to design, build, and analyze a wheelchair scale capable of weighing a wheelchair/person combination of up to 800 pounds. The clients for this scale are members of a support group at the Cleveland Clinic for people who are confined to wheelchairs, in this case, many of which are electric wheelchairs. The scale currently in use does not have a large enough platform or weight capacity to accommodate an electric wheelchair, which is much larger and heavier than a manual wheelchair. The proposed solution is to create a scale with a platform and load capacity to accommodate users who are in an electric wheelchair but will also be usable for manual wheelchairs. This design will be lightweight and easily moveable. This will allow the support group members to track their weight, providing invaluable information about their health.

Design Team: Gabe Hickman, Hanyoung Lim, Travis Siegel, John Gibson

Faculty Advisor: Dr. Mohamed Samir Hefzy, Client Advisor: Dr. Greg Nemunaitis

Project Sponsors: University of Toledo, Mosier Industrial Services, Premier Industrial Machine, Tacuna Systems

Our client lost the use of her legs in an accident and is wheelchair bound. She currently

uses a motorized wheelchair lift to enter and exit her home. During emergencies or

power outages she has to default to a wheelchair ramp since the lift is inoperable

without power. Her current ramp is heavy and bulky and cannot be operated by one person.

The goal of this project was to build a lightweight portable ramp to replace her current

ramp to enable her to enter and exit her home when the lift is without power. In addition,

the client would like the ramp to be universal in use so she can use the ramp to help

her gain access to houses and buildings with small two-step entrances and without

handicap entrances. This is an issue that she encounters when she goes to her parents’

or friends’ houses and she must be lifted over the steps in order to gain access.

Our client lost the use of her legs in an accident and is wheelchair bound. She currently

uses a motorized wheelchair lift to enter and exit her home. During emergencies or

power outages she has to default to a wheelchair ramp since the lift is inoperable

without power. Her current ramp is heavy and bulky and cannot be operated by one person.

The goal of this project was to build a lightweight portable ramp to replace her current

ramp to enable her to enter and exit her home when the lift is without power. In addition,

the client would like the ramp to be universal in use so she can use the ramp to help

her gain access to houses and buildings with small two-step entrances and without

handicap entrances. This is an issue that she encounters when she goes to her parents’

or friends’ houses and she must be lifted over the steps in order to gain access.

Design Team Members: Kyle Robbing - Team Lead; Andrew Schafer - Technical Liaison; Jakob Bohland - Purchasing Agent; Clinton Caddell - Communications Lead

Faculty/Client Advisor: Dr. Mohamed Hefzy - Facility Advisor; Dr. Greg Nemunaitis - Client Advisor

Project Sponsor: MetroHealth

Special Thanks: Dr. Mohamed Hefzy, Dr. Greg Nemunaitis, Dr. Brian Trease, John Jaegly

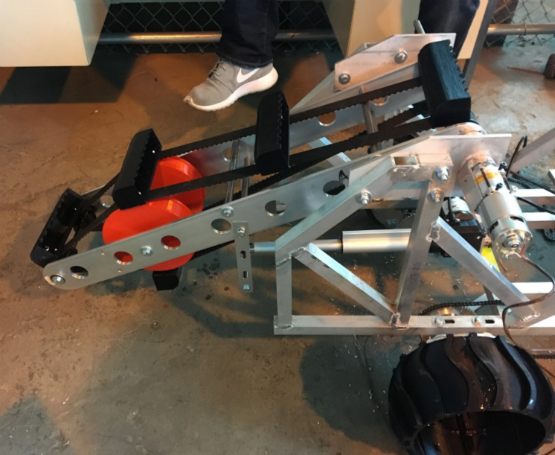

The goal of this project is to go fast, using multiple-people. A previous group designed

a three-person, tandem-style vehicle, and with some gearing modifications, traveled

32 mph. A subsequent group made some aerodynamic modifications and traveled at 36

mph. This semester, the goal is to go faster (safely) by: adding a larger front fairing,

evaluating and improving the brakes as needed, and finishing implementation of a system

that doesn't require all riders to pedal at the same time (like most tandems do).

The goal of this project is to go fast, using multiple-people. A previous group designed

a three-person, tandem-style vehicle, and with some gearing modifications, traveled

32 mph. A subsequent group made some aerodynamic modifications and traveled at 36

mph. This semester, the goal is to go faster (safely) by: adding a larger front fairing,

evaluating and improving the brakes as needed, and finishing implementation of a system

that doesn't require all riders to pedal at the same time (like most tandems do).

Design Team Members: Bradley Boss, Corey Tipton, Peter Duchini, Logan Davies

Faculty/Client Advisor: Adam Schroeder, Dr. Brian Trease

Sponsor: University of Toledo MIME Department

In the past few years Lake Erie has had an increase in algae growth. This growth

limits the amount of oxygen in the water creating dead zones where no aquatic life

can survive. This alga can also make the water unsafe to consume due to a toxin it

produces called microcystin. In hopes of finding a solution to these problems, researchers

must be able to understand how the algae grow, move and where the algae are most highly

concentrated. One way to do this is to take photos during the months in which the

growth is high. There are currently two methods to do this, aircraft and satellites.

Aircraft are expensive to rent and are hindered by inclement weather. Satellites

are limited in the resolution of their pictures since they are so far from the surface.

Our proposed solution is to create a stable aerostat that will fly at about 500 feet

and be able to be left to fly for extended periods of time allowing for greater detail

in the pictures and a longer span of time for more photos and the ability for a time-lapse.

In the past few years Lake Erie has had an increase in algae growth. This growth

limits the amount of oxygen in the water creating dead zones where no aquatic life

can survive. This alga can also make the water unsafe to consume due to a toxin it

produces called microcystin. In hopes of finding a solution to these problems, researchers

must be able to understand how the algae grow, move and where the algae are most highly

concentrated. One way to do this is to take photos during the months in which the

growth is high. There are currently two methods to do this, aircraft and satellites.

Aircraft are expensive to rent and are hindered by inclement weather. Satellites

are limited in the resolution of their pictures since they are so far from the surface.

Our proposed solution is to create a stable aerostat that will fly at about 500 feet

and be able to be left to fly for extended periods of time allowing for greater detail

in the pictures and a longer span of time for more photos and the ability for a time-lapse.

Design Team Members: Kyle Gladieux, Bryan Carolin, Logan Swanger

Faculty/Client Advisor: Dr. Brian Trease, Adam Schroeder

Project Sponsor: Dr. Brian Trease

Special Thanks to Adam Schroeder for Advice & Feedback; Brian Trease for Lab Space & Project Funding; John Jaegly for Assistance With Lab Testing; Patrick Shemenski for help with the 3D Printed Parts; and finally Lucas Palumbo for Electronics

NASA hosts an annual university competition to create and pilot a Mars mining robot.

This is our first time participating in the event, and we have already received $5000

in support from the Ohio Space Grant Consortium. A Senior Design Team initiated the

project last semester, completing many elements of the structure and mobility system.

The current design team worked to complete and test the robot.

NASA hosts an annual university competition to create and pilot a Mars mining robot.

This is our first time participating in the event, and we have already received $5000

in support from the Ohio Space Grant Consortium. A Senior Design Team initiated the

project last semester, completing many elements of the structure and mobility system.

The current design team worked to complete and test the robot.

Teams have 10 minutes to navigate a course representing Martian surface conditions. The goal during is to collect as much gravel (which simulates icy regolith) from below the surface of a silty terrain. The gravel must then be transferred back to a collection bucket; points are awarded for the amount collected. Points are also deducted based on robot weight, energy usage, and wireless bandwidth usage. The robot must be under 80 kg and fit within a 1.5 x 0.75 x 0.75 m volume.

Design Team Members: James Sabatka- Team Leader; Elisabeth Emane- Technical Liaison; Patrick Luettke- Purchasing Agent; Justin Soncrant – Web Page Specialist

Faculty/Client Advisor: Professor Brian Trease

Project Sponsor: University of Toledo

The current NASA Starshade optical shield cannot support its own weight under Earth’s

gravity. It is supported with a counterbalance system which utilizes wires, pulleys,

and counterweights. The purpose of this project is to design a wrapped-rib structure

for the Starshade optical shield that can easily be integrated into the current design.

The newly integrated ribs will provide support to the blanket in order to prevent

drooping.

The current NASA Starshade optical shield cannot support its own weight under Earth’s

gravity. It is supported with a counterbalance system which utilizes wires, pulleys,

and counterweights. The purpose of this project is to design a wrapped-rib structure

for the Starshade optical shield that can easily be integrated into the current design.

The newly integrated ribs will provide support to the blanket in order to prevent

drooping.

Design Team Members: Alexander Binder, Mark Gore, Nai-Ning Kuo, Steven Will

Faculty/Client Advisor: Dr. Brian Trease - Faculty Advisor; Dr. Manan Arya - Client Advisor

Project Sponsor: UT MIME Department Senior Design Program; JPL Center for Academic Partnership

Special Thanks: Dr. Brian Trease, Dr. Manan Arya

The goal of this project is to model and analyze a novel technology related to hydro

power.

The goal of this project is to model and analyze a novel technology related to hydro

power.

Design Team Members: Alex Zaleski, Alex Meier, Jon Reisig, David Martinek

Faculty Advisor: Dr. Sorin Cioc; Client Advisor: Mark Anteau

Project Sponsor: Mark Anteau

Special Thanks: Dr. Sorin Cioc, Mark Anteau, The University of Toledo, The UT College of Engineering, Patrick Shemenski, The Reisig Family

The purpose of our project is to permit, design, and estimate a solar array project

for the University of Toledo. Our client is Michael Green, the director of energy

management for the University of Toledo, who has allowed us to take over the project

that he had begun. Dr. Randy Ellingson is our advisor and student Jason Gonring will

be assisting in the design process. First Solar donated over 1,000 solar panels to

the University to be used however we wish.

The purpose of our project is to permit, design, and estimate a solar array project

for the University of Toledo. Our client is Michael Green, the director of energy

management for the University of Toledo, who has allowed us to take over the project

that he had begun. Dr. Randy Ellingson is our advisor and student Jason Gonring will

be assisting in the design process. First Solar donated over 1,000 solar panels to

the University to be used however we wish.

Our group has the main tasks of deciding the location for the panels, designing the layout of the array, working with a racking and inverter supplier, providing the necessary construction documents, and estimating the cost of the project. The end goal is to have the entire project planned out by the end of the semester, and have it approved by the Vice President of Facilities and Construction so that the project can begin construction by the beginning of summer 2018.

Design Team Members: Alex Demory, Matthew Snyder, Samantha Hunt, Jacob Smith

Faculty/Client Advisor: Dr. Randall Ellingson, Jason Gorning, Michael Green

Special Thanks: First Solar, UT Student Green Fund, University of Toledo Facilities and Operations, Dr. Randy Ellingson, Michael Green and Jason Gonring

When below freezing temperatures combine with snow accumulation on the roof and the

house temperatures that melt snow on the majority of the roof, the melted snow refreezes

near the gutter causing potentially damaging ice damming. We are proposing a system

that will spray de-icing fluid on the roof and gutter to prevent ice damming.

When below freezing temperatures combine with snow accumulation on the roof and the

house temperatures that melt snow on the majority of the roof, the melted snow refreezes

near the gutter causing potentially damaging ice damming. We are proposing a system

that will spray de-icing fluid on the roof and gutter to prevent ice damming.

Design Team Members: Samantha Perry, Evan Pelton, Alex Medley, Ryan Czajka, Nick Wilson, Javier Salazar, Jacob Strohscher

Faculty Advisor: Dr. Sorin Cioc

Project Sponsor: Tony Jiannuzzi

Special Thanks: Leaf Filter

The objective of this project is to design, analyze, build and test a device that

will help reduce the amount of plastic that escapes into the environment every year.

The client is currently a strong advocate for the reduction of pollution into the

environment and recycling, these two factors combined produced the idea of a plastic

densification machine to help eliminate point source emissions and increase consumer

participation. The proposed solution is to design a working system with two main sections.

The first section is a size reduction mechanism primarily an industrial shredder to

decrease the plastics to the size of confetti. The second section involves a heated

funnel to a plastic mold in order to produce plastic blocks. This will not only reduce

the amount of plastics that are able to enter into the environment, but will also

open up the opportunity for aid groups and developing nations to use these blocks

as cheap building materials in cases of refugee camps, disaster relief, and other

cases of short term living and development. The prospects for this technology can

eventually branch into other industries and help reduce plastic waste in the environment

by turning it into a useful product.

The objective of this project is to design, analyze, build and test a device that

will help reduce the amount of plastic that escapes into the environment every year.

The client is currently a strong advocate for the reduction of pollution into the

environment and recycling, these two factors combined produced the idea of a plastic

densification machine to help eliminate point source emissions and increase consumer

participation. The proposed solution is to design a working system with two main sections.

The first section is a size reduction mechanism primarily an industrial shredder to

decrease the plastics to the size of confetti. The second section involves a heated

funnel to a plastic mold in order to produce plastic blocks. This will not only reduce

the amount of plastics that are able to enter into the environment, but will also

open up the opportunity for aid groups and developing nations to use these blocks

as cheap building materials in cases of refugee camps, disaster relief, and other

cases of short term living and development. The prospects for this technology can

eventually branch into other industries and help reduce plastic waste in the environment

by turning it into a useful product.

Design Team Members: Brandon Brown, Govind Giri, Jeremy Scott, Christopher Solly

Faculty/Client Advisor: Dr. Hossein Sojoudi

Project Sponsor: Mr. Scott Steele

Special Thanks: The University of Toledo Maker Space Society, Dr. Hossein Sojoudi, Mr. Scott Steele

The objective of this project is to design a space for the University of Toledo’s

students to be the center of self-initiated design and innovation that supports all

students, design courses, and student groups. Availability, flexibility and community

are the main concerns when considering the design of the space. The College of Engineering

wants the space to be available at a variety of times to best accommodate the students'

schedules. A wide range of machines, tools, technology and resources will make the

space flexible to help students with all of their needs. Location of the space will

have a supportive atmosphere being surrounded by computer labs, dining options, classrooms,

other students and faculty.

The objective of this project is to design a space for the University of Toledo’s

students to be the center of self-initiated design and innovation that supports all

students, design courses, and student groups. Availability, flexibility and community

are the main concerns when considering the design of the space. The College of Engineering

wants the space to be available at a variety of times to best accommodate the students'

schedules. A wide range of machines, tools, technology and resources will make the

space flexible to help students with all of their needs. Location of the space will

have a supportive atmosphere being surrounded by computer labs, dining options, classrooms,

other students and faculty.

Design Team Members: Bradley Mullins, Jessica Ostrowski, Elijah Owens, Timothy Schleicher, Benjamin Szirony, Nikota Voigt

Faculty/Client Advisor: Dr. Matthew Franchetti

Project Sponsor: Hotmer Family

Special Thanks: Dr. Matthew Franchetti, The Hotmer Family, The University of Toledo, The College of Engineering, The UT Maker Society, The BiG Fab Lab

The wolves at The Toledo Zoo are very active and highly intelligent creatures. Our

goal as a senior design group is to design an interactive way to feed and entertain

the wolves. Our client would like for our group to design a standing platform that

challenges the wolves to be creative and work together. The exhibit contains three

brother wolves, Lobo, Loki, and Tundra. The wolves are 4 years old and highly intelligent.

They are very destructive and will find a way to destroy nearly anything.

The wolves at The Toledo Zoo are very active and highly intelligent creatures. Our

goal as a senior design group is to design an interactive way to feed and entertain

the wolves. Our client would like for our group to design a standing platform that

challenges the wolves to be creative and work together. The exhibit contains three

brother wolves, Lobo, Loki, and Tundra. The wolves are 4 years old and highly intelligent.

They are very destructive and will find a way to destroy nearly anything.

Currently, these wolves are occupied by a variety of treats and toys. They like grapevine wreaths filled with cat food or other treats; these are good because they force the wolves to work to get their reward. They also are given ribs, pig ears, meat/hide burritos and bones to help keep them occupied. They receive 4 of these items per day, but only one bone per day. They also have some durable balls with holes that can dispense treats or scents that the wolves like to play with. They also have some deck brushes that the zookeepers coat in scents, which the wolves like to rub against for the scent and also to scratch themselves and remove their winter coats. The problem with all of these distractions is that they are short term and the wolves will finish them or get bored of them within a few hours.

The puzzle-platform is a design that is able to be loaded heavily with sticks with limitless variations and challenges built by the zookeepers. The larger the stick puzzle, the more time the wolves will expand in solving the puzzle and reaching the reward hidden in the middle. A variation of this design was first implemented by the Dartmoor Zoo for the lioness exhibit. The puzzle-platform for this project is different because it will serve as a den and perch for the wolves in addition to creating a challenging activity

Design Team Members: Justin Stevenor, Brian LaFreniere, Matthew Allard, Luke Hall

Faculty/Client Advisor: Dr. Lesley Berhan

Project Sponsor: Beth Posta, Toledo Zoo

The objective of this project was to design, manufacture, and deliver a new data acquisition

system for the University of Toledo Formula SAE team. This system will facilitate

the collection of race data in order to better design, tune and validate the suspension

system of the Formula car. Our goal was to be able to measure pushrod strain, damper

position, wheel speed, and brake rotor temperature for all four corners as well as

steering angle, brake pressure and acceleration in three axes about the center of

gravity. The construction of the wiring harness must be clean and robust to endure

the rigors of racing and the scrutiny of design judges at competition.

The objective of this project was to design, manufacture, and deliver a new data acquisition

system for the University of Toledo Formula SAE team. This system will facilitate

the collection of race data in order to better design, tune and validate the suspension

system of the Formula car. Our goal was to be able to measure pushrod strain, damper

position, wheel speed, and brake rotor temperature for all four corners as well as

steering angle, brake pressure and acceleration in three axes about the center of

gravity. The construction of the wiring harness must be clean and robust to endure

the rigors of racing and the scrutiny of design judges at competition.

Design Team Members: Derek Denti, Cody Mills, Ian Betz

Faculty Advisor: Dr. Ray Hixon; Client Advisor: Jacob Kennedy

Project Sponsor: University of Toledo Formula SAE

Special Thanks: Cherry Picked Auto Parts of Toledo, Ohio; Dr. Hixon; University of Toledo Formula SAE Team; Jacob Kennedy